The Ultimate Guide to Choosing the Right Heat Sink

Introduction Welcome to “The Ultimate Guide to Choosing the Right Heat Sink for Your Project.” If you’ve ever wondered how to keep electronic devices cool,

Introduction Welcome to “The Ultimate Guide to Choosing the Right Heat Sink for Your Project.” If you’ve ever wondered how to keep electronic devices cool,

Heat management is a critical factor in the performance and longevity of these devices. We’ll explore the challenges of miniaturization, the importance of efficient heat dissipation, and factors influencing heat sink selection. From active to passive solutions, material considerations to advanced cooling techniques.

Heat sinks solutions are implemented into the automotive industry based on the requirements of your vehicles. You have to keep in mind several possible factors such as the performance of your vehicles, driving time, total heat produced, speed, and much more. For example, if you drive a car at higher speeds, its engine gets warmed. As a result, more heat is produced.

Die cast heat sinks is made from die casting process that involves pressurizing the molten metal into die cast tooling and resulting a certain shape. It’s very suitable for mass production because of the high efficiency but cheap price.

Die cast heat sink functions with another pre-designed component to keep that component cool. It aims to enhance the functions and performance of the design attached to it.

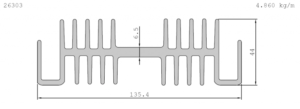

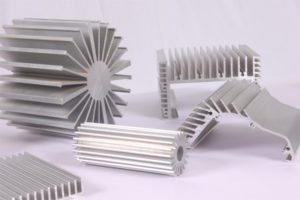

Heat sinks made from aluminum materials are known as aluminum heat sinks. These heat sinks are known to have the highest thermal conductivity with low strength. Manufacturers use different grades of aluminum in the production of heat sinks. Normally used aluminum grades are 6063, 6061, 6060, or 1050. Each has its features and benefits.

Heat sink manufacturers are all around the world but choosing the right one can be a challenge. The United States has one of the largest industries when it comes to heat sink, multiple companies are providing high-quality heat sinks with varying features. You may feel confused about partnering with the right supplier in the USA. This is what you will learn in this article.

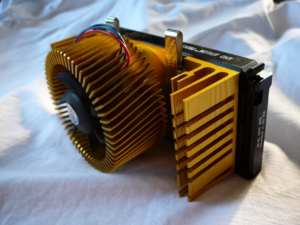

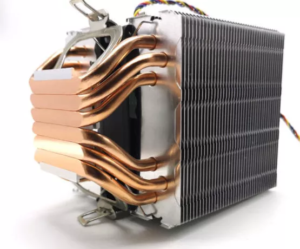

A heat pipe heat sink helps your device to dissipate heat due to its extremely large thermal conductivity. In other words, heat pipe heat sinks are referred to as evacuated vessels. These evacuated vessels are circular in cross-section. Moreover, you will see a liquid that is back filled in those evacuated vessels of heat pipe heat sinks.

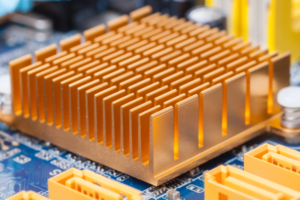

Copper Heat Sinks:

Thermal conductivity is 40% higher than aluminum

Cost is higher than aluminum heat sink

Better thermal performance

Aluminum Heat Sinks

Less Weight

More popular option

Great variety in designs, costs, and colors.

In this comprehensive guide, we’ll walk you through everything you need to know about heat sinks, including what they are, how they work, and the different types available. We’ll also give you tips on how to choose the best one for your specific application.

So whether you’re looking for your first heat sink or just want to learn more about this essential component, read on!

Heat sinks are devices used for cooling objects that get hot while being used. Nowadays, a large number of electrical and mechanical objects use heat sinks to effectively dissipate their heat. So what does a heat sink do?

Pioneer Thermal is your one-stop heat sink supplier, we support design, simulation, prototype build, low volume run and serial order production.

Your drawing and projects are safe with us, we will not disclose any information without your approval.

Or send email to mia@ptheaksink.com directly