Leading Custom Heat Sink Manufacturer with Over 22 years of Excellence

From design to prototype to production, we can meet all your needs.

We will assign a sales from China, USA or Singapore, wherever is near you, to get in touch with you.

22 Years

Heat sink manufacturing and designing experience

22M+ Parts

We built

3k Design

We created

100+ Stable Clients

Over the world

Meet Us

- Based on Dongguan China, manufacturing site in China and Vietnam. Branch office in USA and Singapore.

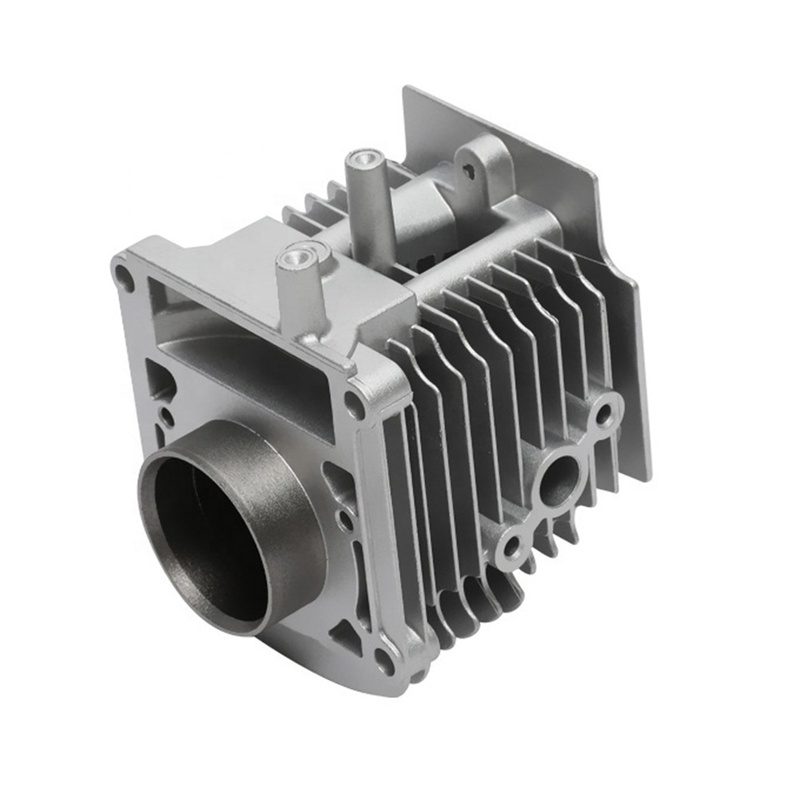

- 130,000 square foot facility with mature production line covering CNC machining, extrusion, stamping, cold forging, die casting, skiving fin, heat pipe assembly, water cooling plate, friction stir welding, vapor chamber, heat sink assembly.

- 22 years experience in custom heat sink design and manufacturing

- Thermal engineer can design heat sink tailored to your needs within 1 days.

- ISO9001 & ISO14001 & IATF16949 certified

- ODM & OEM service available

Pioneer Thermal Heat Sink Manufacturer

What We Can Do For You

01

Detail drawing review in initial stage, such as critical to function (CTF) dimension, tolerance, flatness, manufacturing process feasibility.

02

Design for Manufacture (DFM) is always prepared and sent along with quotation

03

Free design and thermal analysis can be provided before prototype build, to ensure the thermal solution is right for your application

04

Microsoft Teams Meeting can be arranged with you to discuss technical points & project status directly

05

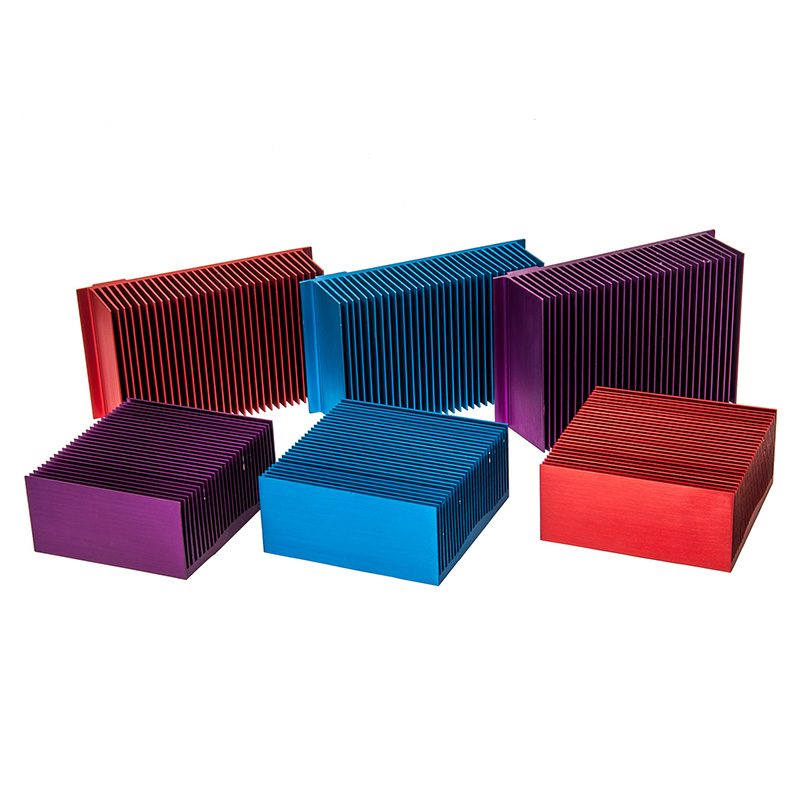

Tight tolerance, strict flatness and different surface treatment is achievable for different heat sink types

06

Quick prototype building for custom heat sink within 7 days

07

Support small trial run with no MOQ required

08

In-house production line to offer short lead time for serial order

09

Rich experience in various industry like electronic, automotive, LED, server etc., very familiar with the quality standard so you have no worries about the heat sink quality and save the back-and-forth time

From Prototype to Production

Comprehensive heat sink manufacturing ability to meet all your needs

On-Demand Manufacturing Solutions

Whether you need prototype to test the heat sink thermal function, or you need big quantity for on-going project, we have the perfect solution.

Rapid Prototype

7 days for prototype building

Trial Run

Trial run is acceptable before going to mass production

Mass Production

Mature production line and advanced machining equipment to meet your lead time and quality demand.

Assembly

Assembly service (screw, spring, fan, pad etc.) is provided.

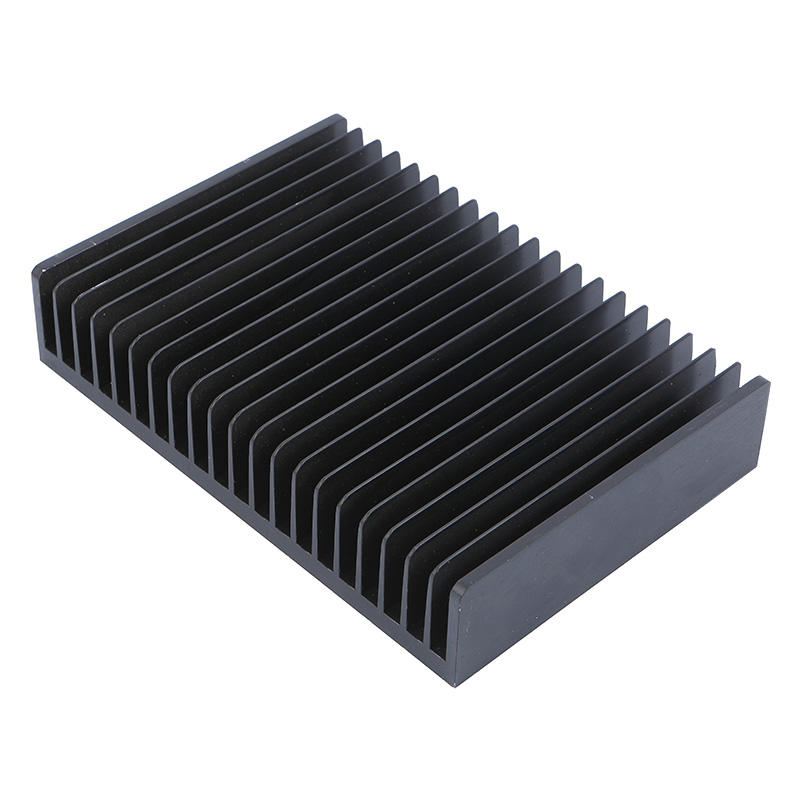

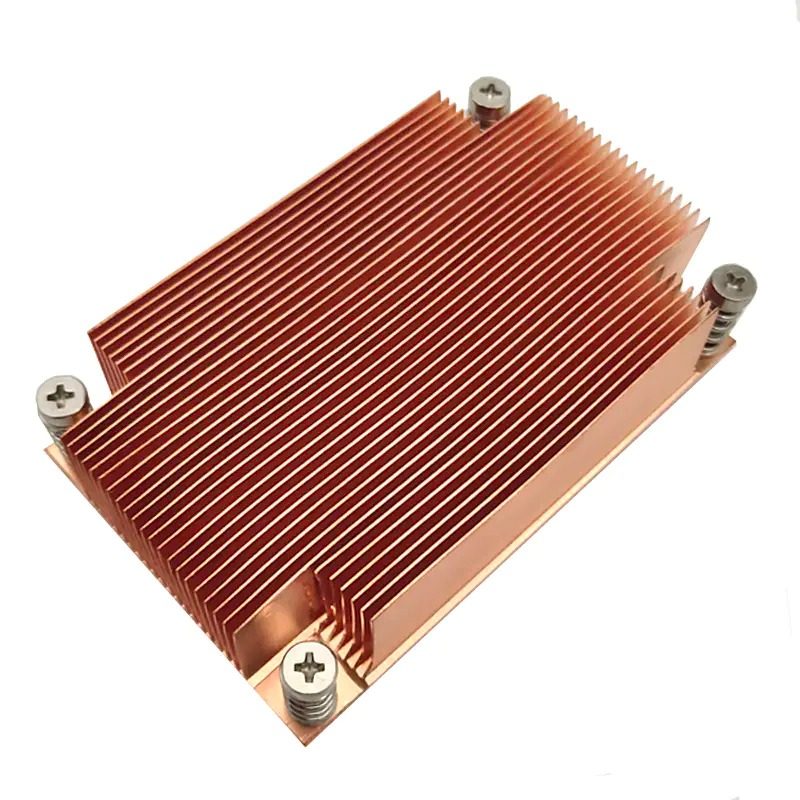

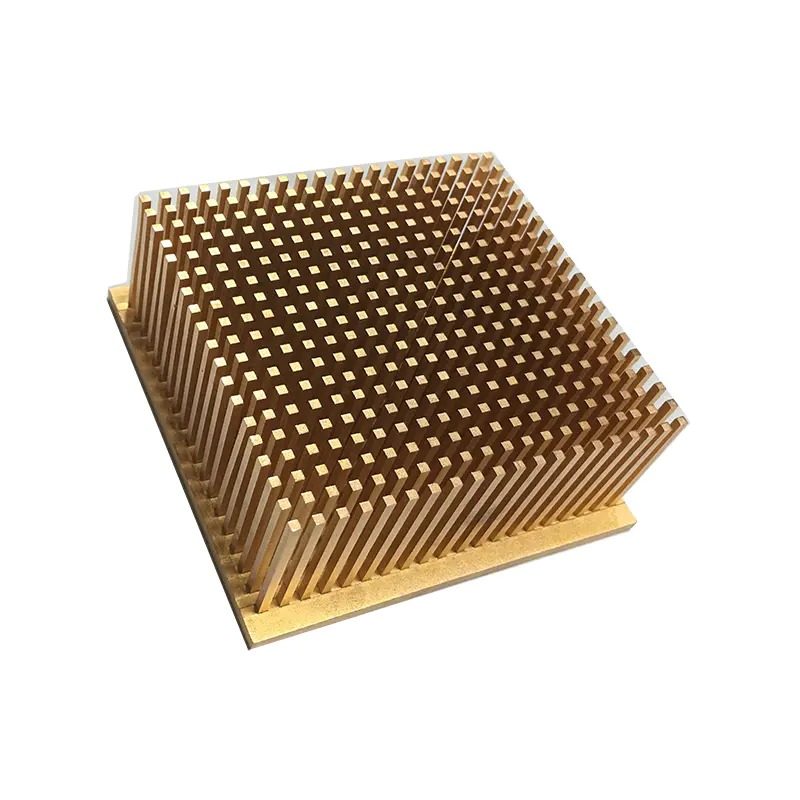

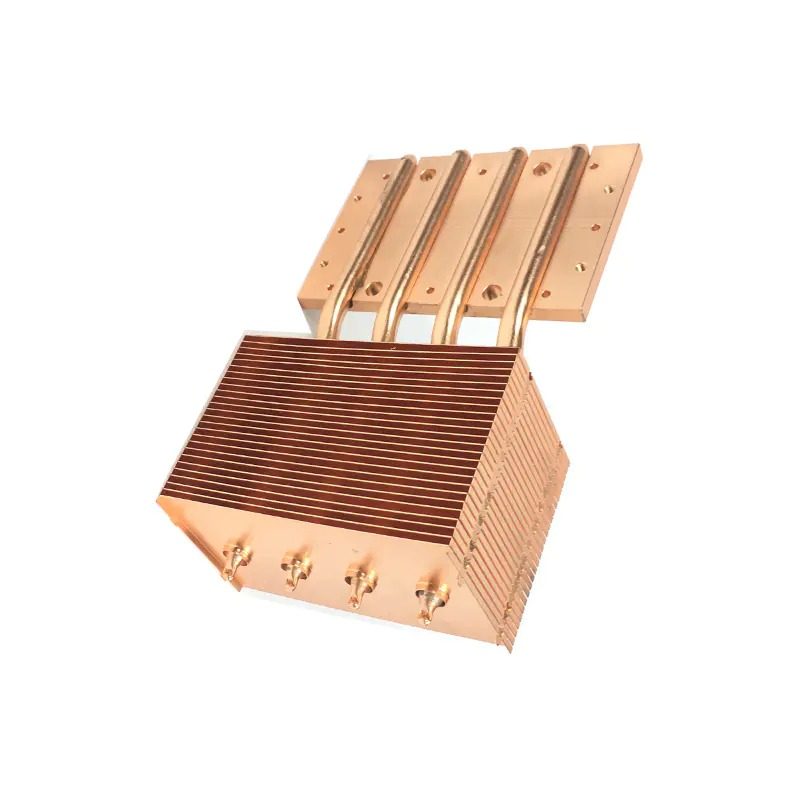

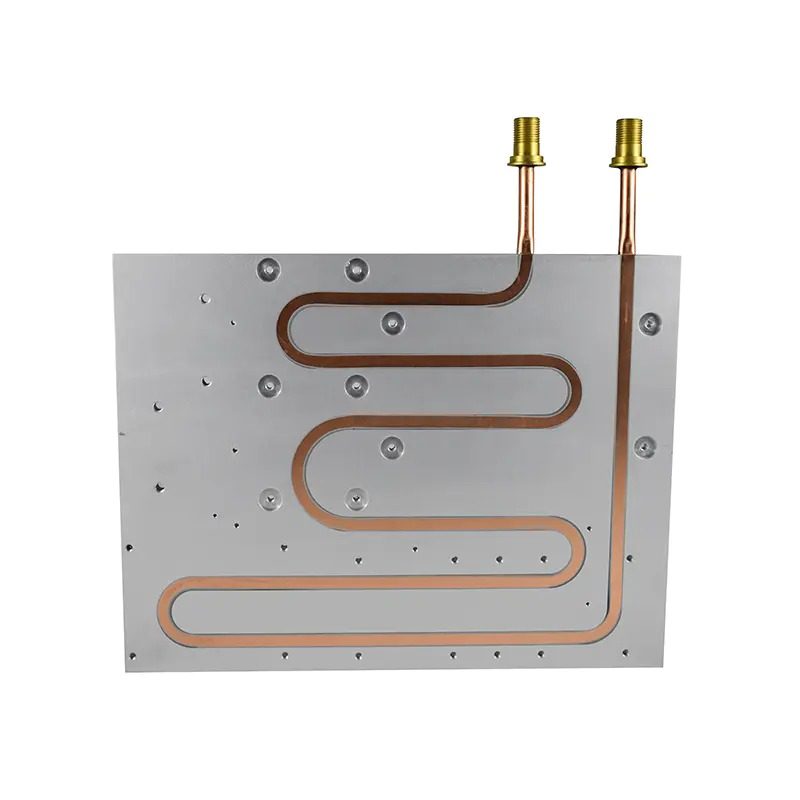

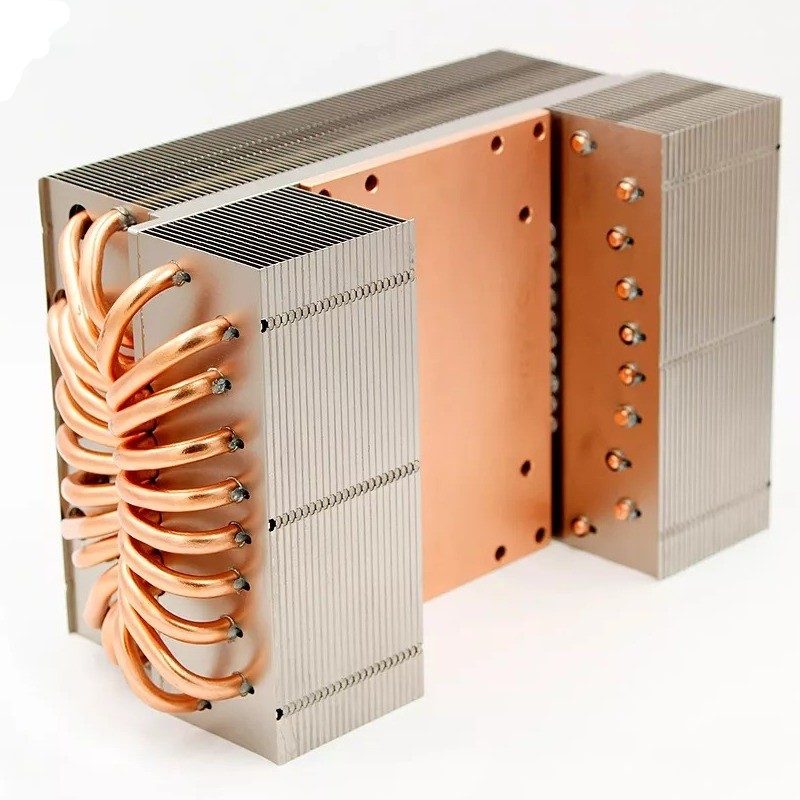

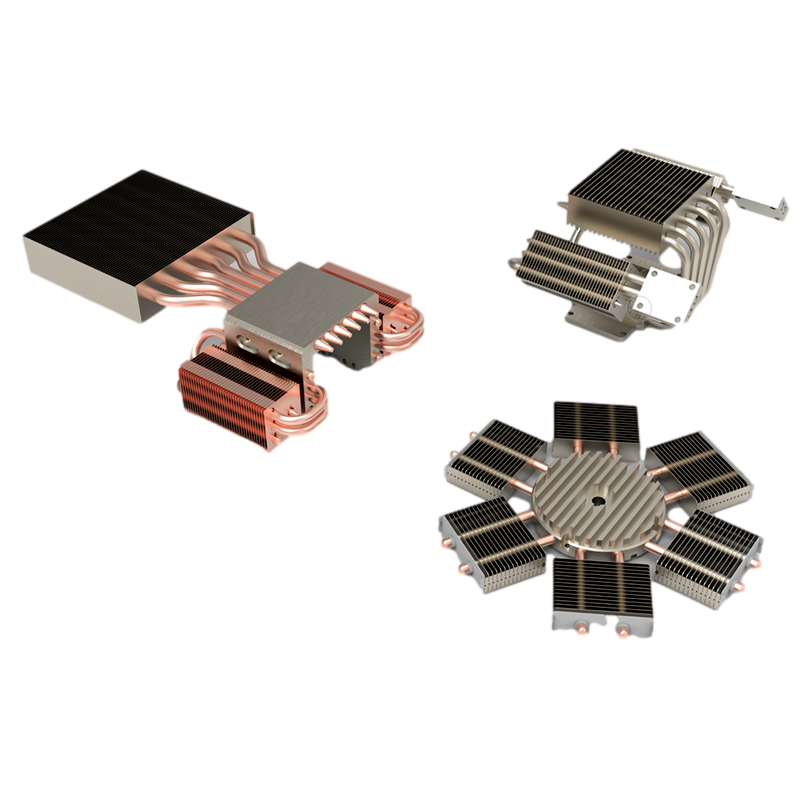

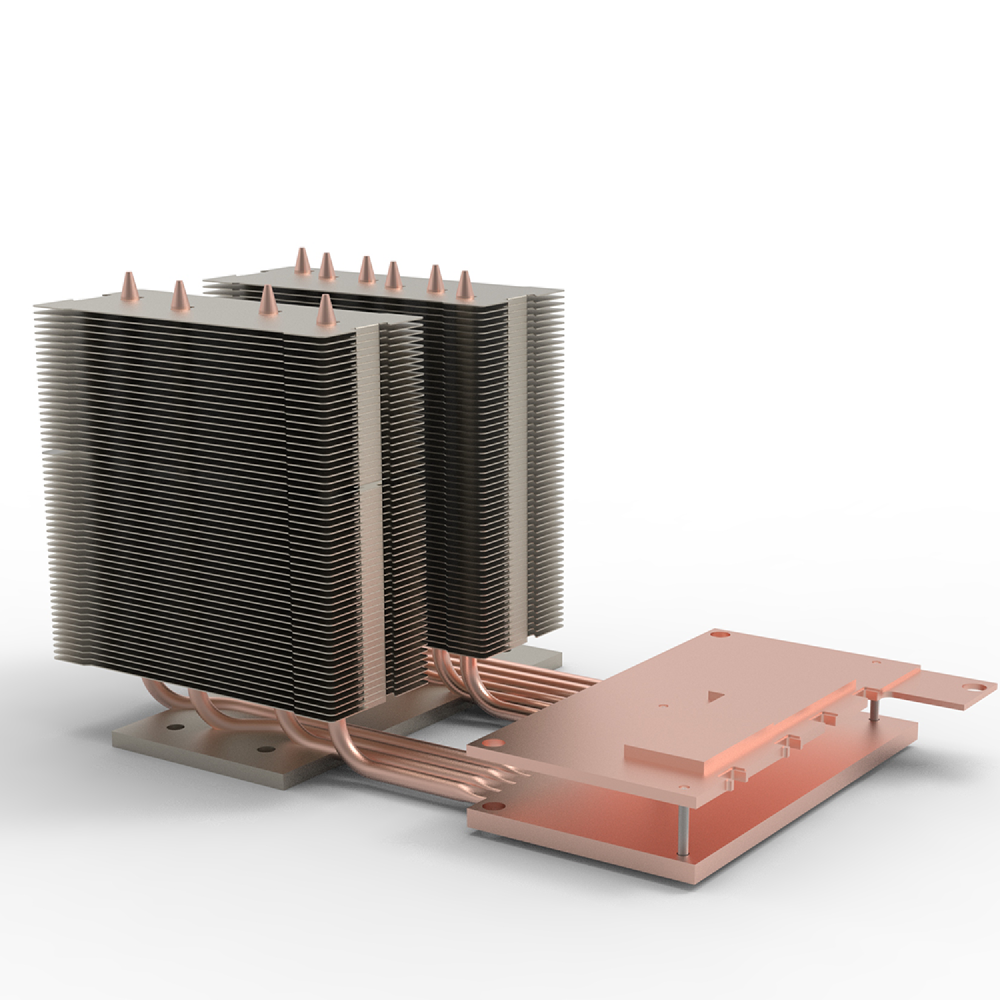

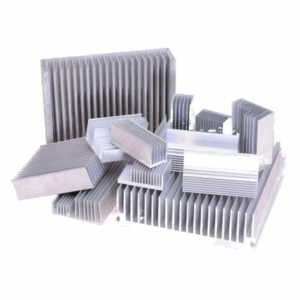

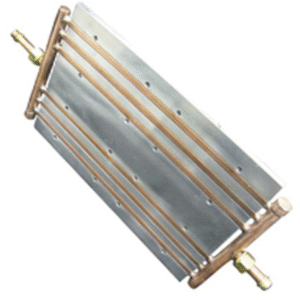

Pioneer Thermal is a custom heat sink manufacturer and suppliers that offer a variety of heat sink manufacturing to meet all your needs, include extrusion heat sink, skived heat sink, stamped fin heat sink, forged heat sink, die cast heat sink, heat pipe heat sink, water cooled heat sink, brazed heat sink, vapor chamber. We also provide various surface treatments, such as nickel plated, anti-oxidation, electrophoresis coating, chromate, anodizing and powder coating etc. With our state-of-art equipment and production line, we have great heat sink manufacturing capability, to provide the high quality but cost-effective heat sink for our customers all over the world. Contact Us now to find out how we can benefit your heat sink business.

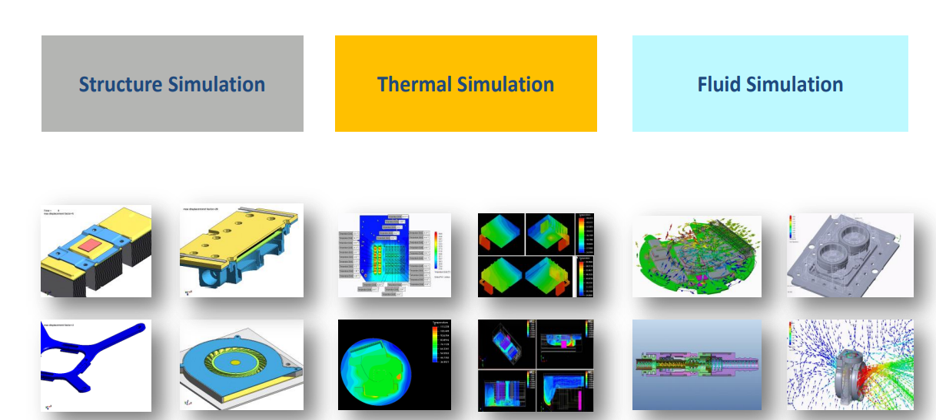

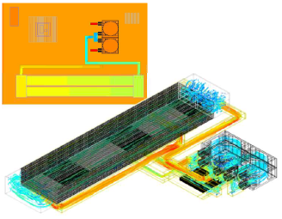

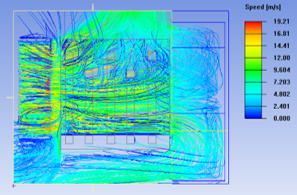

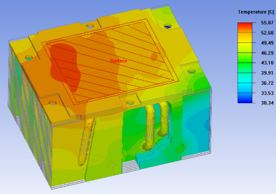

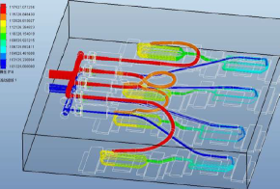

Simulation & Design Service

No worries, we can simulate your own heat sink design to verify the thermal performance, or design a complete new heat sink suitable for your device.

Need Heat Sink Design?

Our seasoned engineer can design heat sink based on customers’ heat dissipation needs, and model and critique the thermal implications of customers’ design using CFD, Solidworks, ProE, and AutoCAD. This enables us to create functional thermal solutions that meet the demanding cooling requirements in the most efficient and cost-effective way possible. We can manage customers’ thermal needs from the conceptual design stage, through prototypes and into production.

Industries We Served

We have provided high quality heat sinks for various industries around the world

Consumer electronics

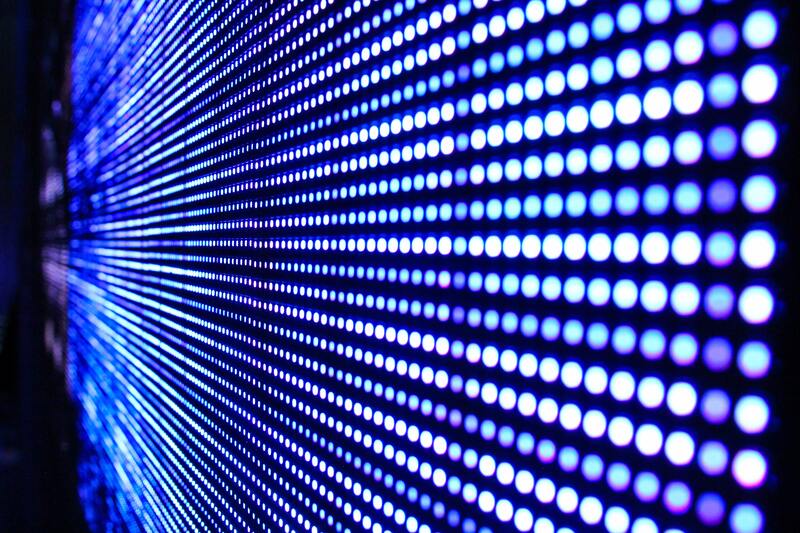

Led

server

data center

Power Supply

Medical Equipment

Telecom

Automotive

New energy

Photovoltaic

Military

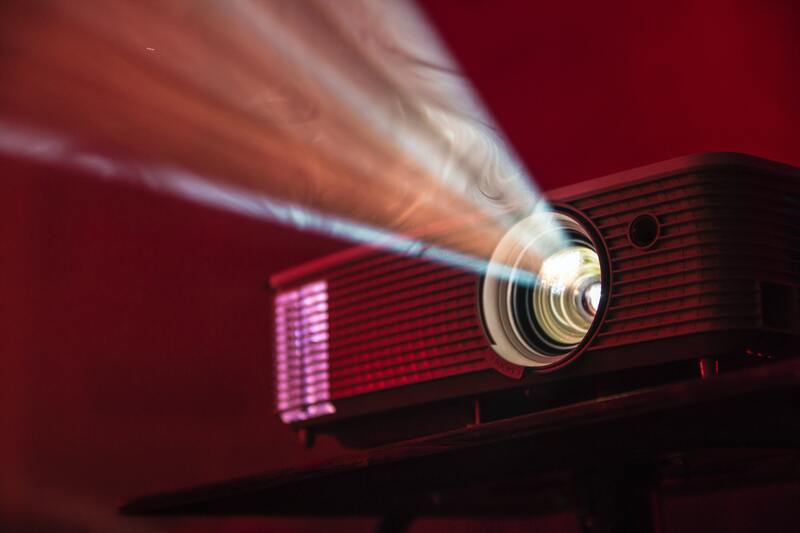

Projector

Feedback From Our Customer

Pioneer Thermal is our favorite heat sink supplier, they always deliver product in time with good quality. Sometimes our project is in a rush, Pioneer Thermal will make proper production plan and advance the delivery time for us.

John Schutze

Product Engineer

It is always a joy to work with Pioneer Thermal, they always response fast. What I like them most is that they help us to design, run simulation and build prototype before we go to mass production stage, this saves us a lot of time and cost.

Nelson Seiberl

Project Manager

Pioneer Thermal is a long time heat sink partner for our company. I enjoy very much with working with them, they always give good suggestions to make my design more producible and cost-affordable.

David L. Beckley

Design Engineer

FAQ

Yes, our factory located in Dongguan City, China. You can find the detail location on the About Us page. If you are not able to visit us due to COVID-19, we can have a video call to give you a factory tour.

Incoming material inspection, FAI, IPQC, OQC is performed for every order.

Quality comes from improvement of the production process, and that’s what we do.

We will do OQC for every shipment and make sure you get the good parts, but in case you receive any defect part, we will immediately make the analysis and find the root cause to prevent happening again. And meanwhile we will send new replacement with no excuse.

Yes, we have cooperated shipping company. Carrier, air freight, sea shipment, whatever you choose, we can arrange for you.

Fairs and Events

We are looking forward to meeting you!

Welcome to visit us at exhibition.

We'd Love To Hear From You

Hi partner, no matter you need new design & simulation for your new project, or you need heat sink manufacturing service for current on-going project, we are at your service.

What You Get When You Send Inquiry

- Less than 12 hours response to your message

- Professional advice on manufacturing process

- Seasoned design engineer help you to design a heat sink tailored to your needs

- Mature production line to save your cost

- Seamless communication to save your time

- A one-stop partner to make your work easier

You can always send inquiry with drawing to mia@ptheatsink.com

Latest Blog

Why Cold Plates Are Essential in High-Power Electronic Devices?

Cold plates for electronics are the most effective way to cool high-power devices that generate more heat than fans or standard heat sinks can handle.

Why Extrusion Heat Sinks Are the Go-To Choice for Thermal Management?

Extrusion heat sinks are crucial components in efficient thermal management, ensuring your electronic systems remain calm, safe, and efficient. Effective thermal management is the secret

How Extruded Aluminum Heatsinks Improve Cooling Efficiency?

In today’s world, where everything from computers to cars relies on electronic systems, keeping those systems cool is more important than ever. Without proper cooling,

The Role of Stamping Heat Sinks in Compact Device Cooling!

As electronic devices get smaller and more powerful, the need to manage heat becomes more important than ever. Overheating can damage internal components, reduce performance,

Custom Heat Sink Manufacturer Guide: Benefits Over Standard Heat Sink Suppliers

Have you ever wondered why some electronic systems run flawlessly while others overheat and shut down, even when using the same parts? The secret often

The Role of Custom Liquid Cold Plates in Advanced Thermal Systems

Have you ever wondered how powerful machines—like electric cars, MRI scanners, or massive data servers—keep from overheating? With all the heat they produce, it’s a