Are you looking for a water cooled heat sink for your next project? If so, you may be wondering how to choose the right one. There are a lot of different options available on the market, and it can be tricky to decide which one is right for you. In this blog post, we will discuss some of the key factors you need to consider when choosing a liquid cooled heat sinks. We will also provide some tips on how to find the best one for your needs.

What is a water cooled heat sink?

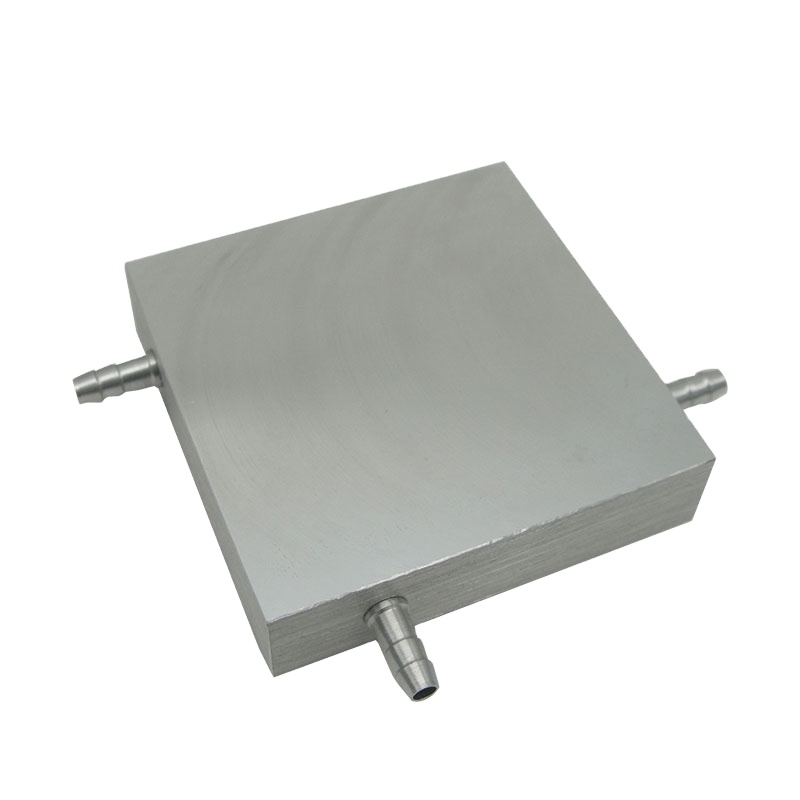

A water cooled heat sink is a device that uses water to absorb and dissipate heat away from an object or area. Water has a higher specific heat capacity than air, meaning it can absorb more heat before reaching its own boiling point. This makes it an ideal choice for cooling high-powered electronic components that generate a lot of heat or for providing cooling during extended periods of operation. The advantage of using a liquid cooled heat sinks is that it can dissipate heat more effectively than air cooling. This is because water has a higher specific heat capacity than air, meaning it can absorb more heat before it starts to feel hot. Additionally, water is a better conductor of heat than air, so it can help to transfer heat away from the device more effectively.

Factors to consider when choosing a water cooled heat sink

There are a few key factors that you need to consider, the following guide will help you to choose the right one for your needs:

– The size of the heat sink. This is important as you need to make sure that the heatsink is large enough to dissipate the amount of heat generated by your components. If it is too small, it will not be effective and your components will overheat.

– The type of liquid cooling system you are using. There are two main types of liquid cooling systems – closed loop and open loop. Closed loop systems are sealed and do not require any maintenance, whereas open loop systems need to be refilled with water periodically.

– The noise level. Some water cooled heat sinks can be quite loud, so you need to make sure that it will not be too disruptive – The price. Water cooling heat sink can range in price from a few dollars to hundreds of dollars. You need to find one that fits your budget and meets your needs.

– The price. Water cooling heat sink can range in price from a few dollars to hundreds of dollars. You need to find one that fits your budget and meets your needs.

How to find the best water cooling heat sink for your needs

The water-cooling heat sink is one of the most commonly used types of liquid cooling system for electronic devices. There are six main types of water cooling heat sink:

1. Friction Stir Welded water cooling heat sink

2. Vacuum Brazed water cooling heat sinks

3. Tube Embedded water cooling heat sinks

4. Die Cast Liquid water cooling heat sinks

5. Extruded Liquid water cooling heat sinks

6. Gun Drilled Liquid water cooling heat sinks

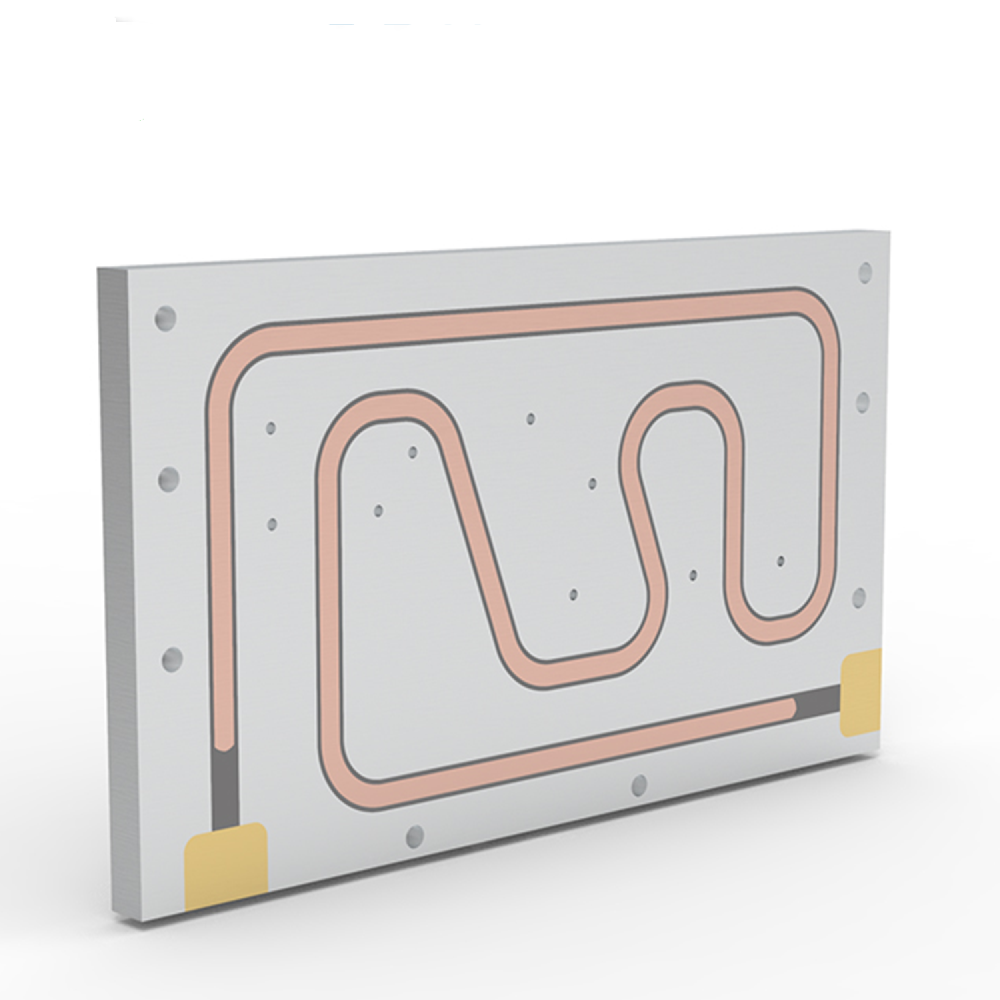

Friction Stir Welded (FSW) liquid cooled plates are the most common type of liquid cooling heat sink, which is a solid-state joining process that uses a non-consumable tool to forge the joint area between two similar or dissimilar materials.

It begins with the placement of the tool on the workpiece. The tool consists of a pin and a shoulder. The shoulder is used to apply pressure to the workpiece, while the pin is rotated at high speeds. As the pin rotates, it creates friction and heat that forge the joint area between the two materials.

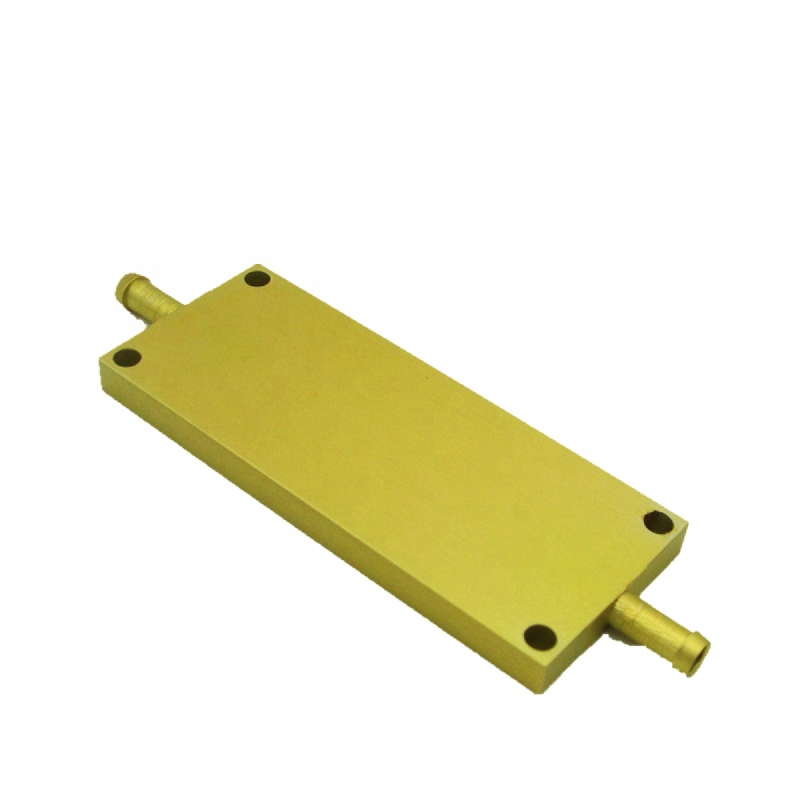

Vacuum brazing is a process of joining two pieces of metal together using a vacuum. The process begins by placing the two pieces of metal to be joined together in a chamber. The chamber is then evacuated to create a vacuum.

Once the chamber has been evacuated, heat is applied to the metals. The heat causes the metals to expand and flow together. As the metals cool, they contract and form a strong bond.

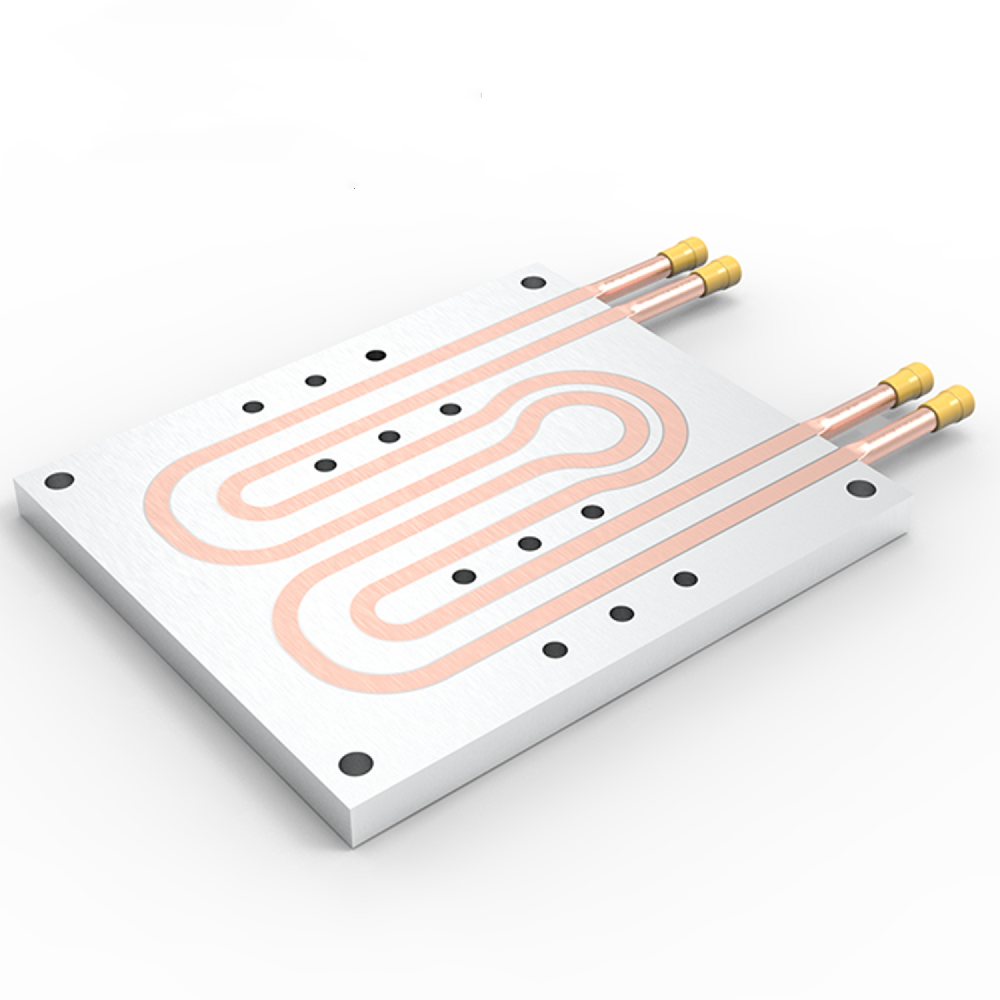

Tube Embedded Cold Plates are made by press fit or epoxy copper tubes/stainless steel tubes to the aluminum base, the liquid only flows inside the tube without any leakage, as well as avoiding the risk of galvanic corrosion due to the formation of micro cells by contacting dissimilar metals.

Extruded Liquid Cooled Plates internal fluid channels are formed by aluminum extrusion, eliminating the high cost of processing, and the two ends are combined in a series/parallel flow path by means of a sealed solid manifold, or FSW.

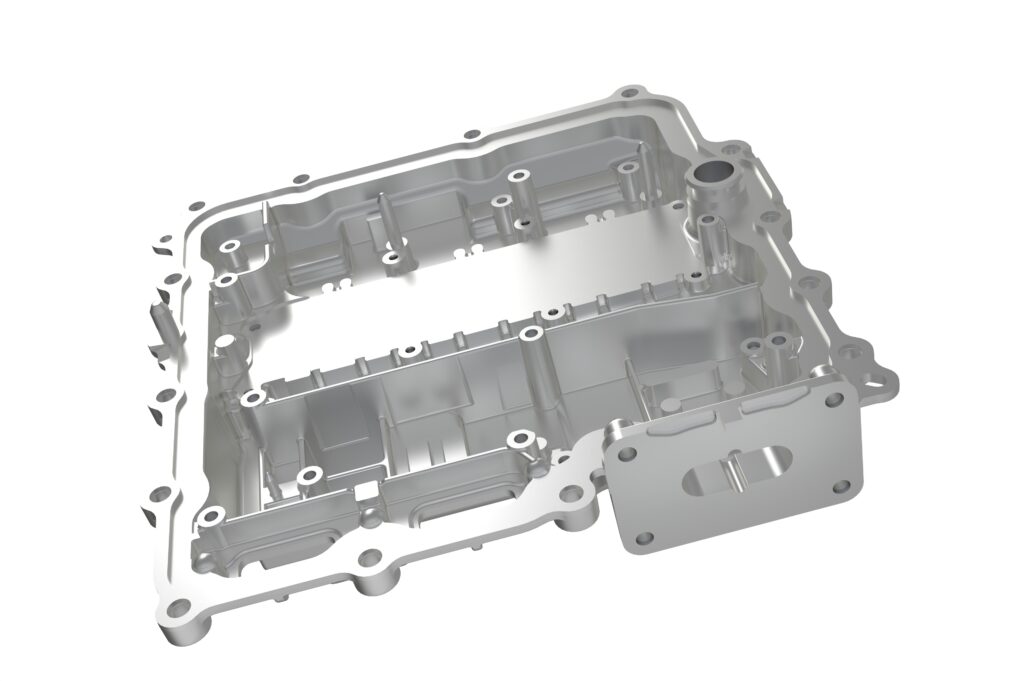

Die Cast Liquid Water Cooling Plates runners are made by die-casting to solve more complex control unit cooling (e.g. EV/HEV batteries or MCUs) at minimum cost.

Gun Drilled Liquid Cold Plates are made by drilling a hole in a piece of metal and then inserting a liquid metal into the hole.

FAQs about water cooled heat sinks

Q: What is the best type of water cooled heat sinks?

A: The best type of water cooled heat sink depends on your needs. Consider the size, material, and thermal conductivity when choosing a heat sink.

Q: What is the difference between FSW and vacuum brazing?

A: FSW uses a consumable wire to join metals, while vacuum brazing uses no melting or consumable materials.

Q: What is the difference between FSW and die casting?

A: FSW uses a consumable wire to join metals, while die casting uses a mold. Die casting is also limited to joining similar materials.

Q: What is the difference between FSW and extrusion?

A: FSW uses a consumable wire to join metals, while extrusion uses a tooling. Extrusion is also limited to joining similar materials. Still have questions about water cooled heat sinks? Contact us today and our experts will be happy to help you.