Leading Aluminum Heat Sink Manufacturer in China

- 21 years aluminum heat sink manufacturing experience

- Free Design

- Mature In-house Production Line

- Comprehensive manufacturing process

We will assign a sales from China, USA or Singapore, wherever is near you, to get in touch with you.

Aluminum heat sinks are a popular choice for electronic devices because they are lightweight and have good thermal conductivity. They are commonly used in computers, TVs, and other electronics that generate a lot of heat. Heat sinks work by dissipating heat away from sensitive components, helping to prevent damage from overheating. Most aluminum heat sinks have a series of fins that increase the surface area for better heat dissipation. In addition, many heat sinks are equipped with fans to help circulate cool air and further reduce the risk of overheating.

Aluminum heat sinks are available in a variety of shapes and sizes, and they can be attached to components using a variety of methods, such as screws, bolts, or clips. In order to work effectively, a heat sink must have good airflow so that the heat can be quickly dissipated. When selecting an aluminum heat sink, it is important to consider the size of the component, the amount of heat that needs to be dissipated, and the available airflow. Using a too small or too large heat sink can impede performance and lead to damages. With proper selection and installation, however, an aluminum heat sink can help to keep your electronic devices running cooler and lasting longer.

Pioneer Thermal provides high-quality aluminum heat sinks for a variety of applications. We offer a range of aluminum heat sink material options, such as AL6061, AL6063, AL6060, AL5083 etc., as well as different surface treatments, such as anodizing, powder coating, nickel plating, E-coating etc., to suit your needs. Our experienced team can help you select the right material and surface treatment for your application. We offer competitive prices and quick turnaround times. Contact us today to learn more about our aluminum heat sink products and services.

Some Aluminum Heat Sink We Made

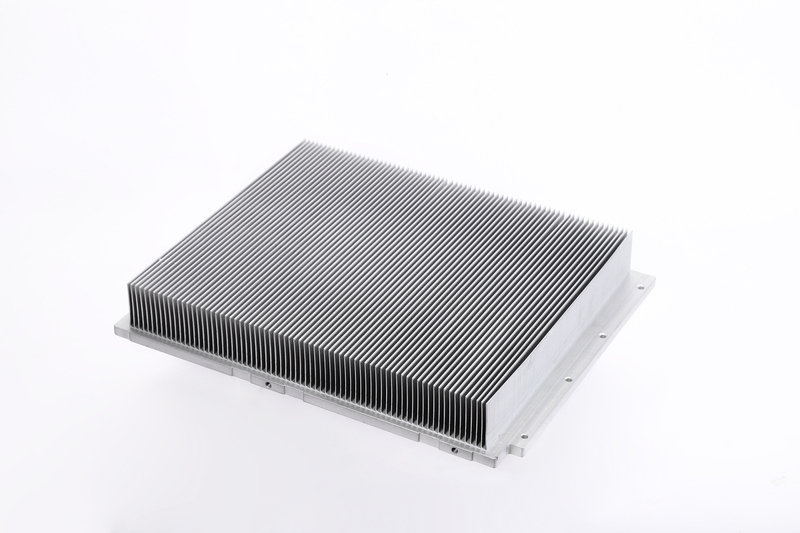

Aluminum Heat Sink by Extrusion Process

Material: AL6063

Process: Extrusion + CNC machining

Finish: Degrease

Quality Control: Calliper, CMM

Aluminum Heat Sink by Forge Process

Material: AL1070

Process: Cold forging + CNC machining + screw assembly

Finish: Degrease

Quality Control: Calliper, CMM

Aluminum Heat Sink by Skiving Process

Material: AL1070

Process: skiving + CNC machining

Finish: Degrease

Quality Control: Calliper, CMM

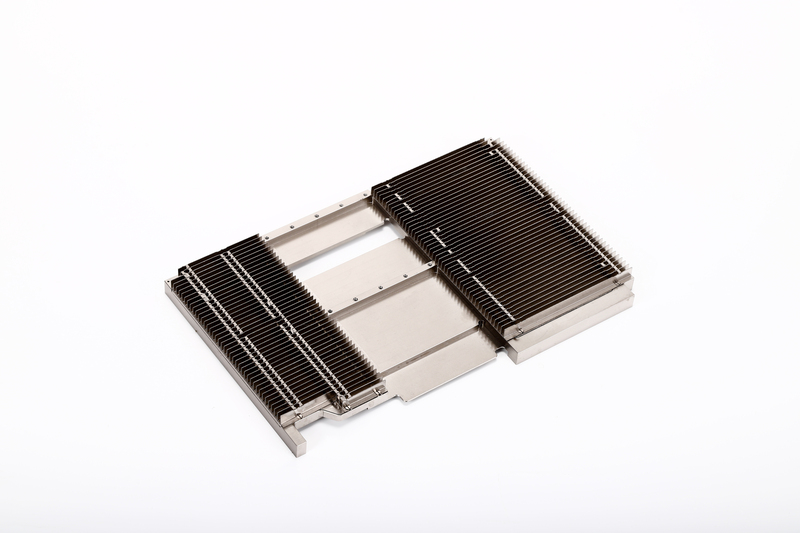

Aluminum Heat Sink by Heat Pipe Soldering Process

Material: Aluminum stack fin + aluminum base plate + heat pipe

Process: Stamping + Soldering + CNC machining

Finish: Nickel plated + anti-oxidation

Quality Control: 100% on-line thermal test, CMM

Aluminum Heat Sink by Vacuum Brazing Process

Material: Aluminum zipper fin + AL3003

Process: Stamping + Vacuum Brazing

Finish: Nickel plated

Quality Control: 100% on-line thermal test, CMM

Aluminum Heat Sink by Stamping Process

Material: Aluminum stack fin + aluminum base plate

Process: Stamping + Soldering + CNC machining

Finish: Nickel plated

Quality Control: Calliper, CMM

Custom Aluminum Heat Sink Manufacturer

If you are looking a custom Aluminum heat sink manufacturer, then Pioneer Thermal is your right choice. We cover all the heat sink manufacturing process, with the industry-leading equipment and mature production line in house, we are able to provide top quality custom heat sink and meantime save your cost.

In addition, our experts always give manufacture suggestions when checking your drawing, or help to create a new design to suit your application.

Main Processes

- Extrusion

- Bonded Fins

- Skived Fins

- Snapped Fins

- Folded Fins

- Heat Pipes

- Cold Forge

- Die Cast

- Friction Stir Welding Cold Plate

- Gun Drill Cold Plate

- Vacuum Brazing Cold Plate

- Vapor Chamber

Finishing Processes

- CNC machining

- Stamping

- Drilling

- Tapping

- Screen Printing

- Anodizing

- Powder Coating

- Electrophoresis

- E-coating

- Chromate

- Passivation

- Laser Etching

- Polishing

Finishing Value Added

- Embedded fans

- Thermal Grease

- Phase Change Materials

- Gap Filler Pads

- Screws

- Springs

- Clips

- Embedded Heat Pipes

- Back Plates

- PEMs

- Standoffs

- Dielectric pads

- Compounds

Why Us

Real Factory

91,000 square feet primary facility to ensure you get the competitive price

Strong production capability

Industry-leading production machines to provide precision parts to ensure you get the exact parts that meets the drawing

One-stop Service

Design to prototype to serial order service to save you a lot of time and work

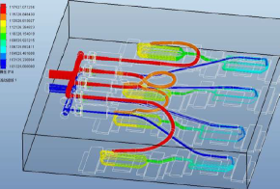

ODM Service

Seasoned engineers design heatsinks based on heat dissipation needs to offer the perfect heat sink suitable your application

Good Quality

Strictly quality control from incoming material to finished goods to ensure high quality and reduce customer complain

Timely Delivery

Specialist to follow up each process to make sure timely delivery and book shipment space in advance so you can get the parts on time

We'd Love To Hear From You

Hi partner, no matter you need new design & simulation for your new project, or you need heat sink manufacturing service for current on-going project, we are at your service.

What You Get When You Send Inquiry

- Less than 12 hours response to your message

- Professional advice on manufacturing process

- Seasoned design engineer help you to design a heat sink tailored to your needs

- Mature production line to save your cost

- Seamless communication to save your time

- A one-stop partner to make your work easier

You can always send inquiry with drawing to mia@ptheatsink.com