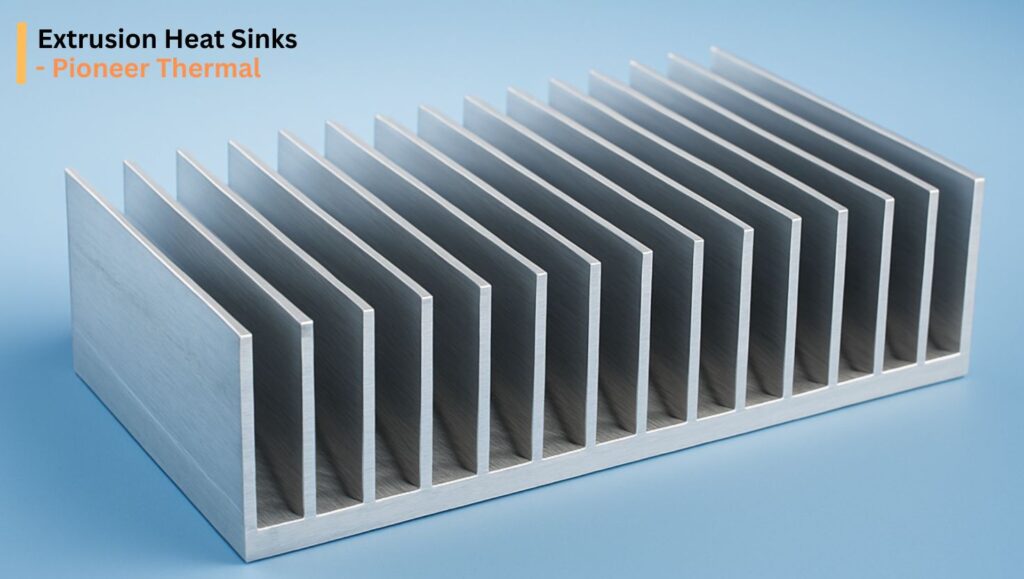

Extrusion heat sinks are crucial components in efficient thermal management, ensuring your electronic systems remain calm, safe, and efficient.

Effective thermal management is the secret to system reliability. I don’t care what the application is – power supplies, LED lighting systems, industrial electronics – there is one solution that keeps on popping up: extrusion heat sinks. They are cheap, efficient, and versatile. Most important, they work. If you’re buying components from a heatsink vendor, it’s worth familiarizing yourself with the specifics of extrusion design and its thermal benefits.

How Fin Profiles Influence Cooling Performance

Extrusion heat sinks are constructed by forcing the aluminum through a die to create long surface areas called fins. It is that surface area that conducts heat away from your components to the air. But its performance is significantly determined by the shape of those fins.

Thinner and broader fins provide more surface area but may limit airflow. Greater spacing between fins enhances natural convection, while closer spacing is best when using active cooling, such as a fan.

Most manufacturers employ 6063-T5 aluminum, which has a good balance of thermal conductivity and machinability. It is perfect for both standard and custom profiles. A professional heat sink manufacturer will help you select the appropriate profile based on your specific cooling requirements.

What it does for you: sink shape is as important as size. Skilful tuning of fin geometry to your application can achieve significant thermal performance improvements without incurring additional expense.

Why Extruded Heat Sinks Still Reign Supreme

There are several options in thermal design, including die-cast, bonded fin, and machined. But extrusion still prevails as the most widespread for a reason.

- Cost-effectiveness for medium to high-volume production runs.

- Ease of customization for lengths, cutouts, or tapped holes

- Lightweight and corrosion-resistant material

- Predictability and reliability in output production

Extrusion finds that sweet spot where performance is wedded to feasibility. That’s why you can find it in everything from consumer electronics to renewable energy equipment.

Experienced heatsink companies appreciate extrusion for its consistency. Designers like it for its versatility. And customers appreciate the cost.

What to Seek in a Quality Heatsink Manufacturer

Now let’s get serious. Choosing the right heatsink supplier can make or break your thermal strategy.

1. Technical Guidance

Design consultation with manufacturers can assist you in customizing your sink to your particular system requirements. That may include fin pitch adjustment, base thickness, or cutout ability.

2. Full-Service Machining

It’s a huge benefit if a supplier can cut, drill, anodize, and finish internally. It reduces lead time and part quality because it’s all done in one building.

3. Tooling and Die Development

If you’re making profiles to order, your producer will guide you through the return on investment. These dies aren’t inexpensive, but they can dramatically reduce your cost per unit if you’re going to be producing in large quantities.

Find a heatsink supplier who treats your part as a performance-critical device, not just an extruded shape.

Prevention of General Heat Sink Design Errors

Even the best-designed extrusion will not function effectively if it is not well integrated. Some of the common issues engineers face are:

1. Packed fins: Excessive fins in natural convection can trap hot air, causing it to rise. Instead of helping, they ruin the airflow. Don’t assume denser is better.

2. Poor thermal contact: If the heat source and heat sink don’t mate properly, your thermal transfer plummets. Use quality interface materials and consistent mounting pressure.

3. Orientation neglect: Natural convection will only function if heat can rise and air can circulate freely. Placing your sink sideways or upside-down is a whole different ball game.

Your heatsink manufacturer should recognize these problems early in the process, particularly during the design review.

When Should Extrusion be the Option?

Extrusion is okay if you need a balance between thermal efficiency and cost. But it’s not necessarily the best for every use.

Select extrusion when:

- You have high to moderate production volumes.

- You require a special mounting or dimension solution.s

- Your design can accommodate a passive heat sink

- Weight is a factor, particularly in aerospace or mobile applications.

Yet, for highly constricted areas or highly high power densities, machined or bonded-fin sinks can be more effective at cooling. Still, for the majority of mid-range applications, extruded heat sinks offer reasonably acceptable performance at a cost that remains within reach.

FAQs

What is the most prevalent material used for extruded heat sinks?

Aluminium 6063-T5. It has a good balance of machinability, strength, and thermal conductivity.

Can fin spacing actually impact thermal performance?

Yes. Further spacing in passive cooling provides improved air flow. In forced-air systems, closer-spaced fins provide additional surface area and enhanced cooling.

Is anodizing required?

It is not required, but it is beneficial. Anodizing raises the corrosion resistance and improves emissivity, enabling the sink to release heat more efficiently.

Are custom profiles worth the investment?

If your application requires an unusual shape or higher thermal output, yes. While a custom die is more costly initially, it’s well worth the longer-term performance and per-unit cost for high-volume applications.