Introduction

Are you finding it hard to decide between selecting a vapor chamber or a liquid cooling plate? This is what you will get to know in this piece of blog. Let’s start with the basics of the vapor chamber and liquid cooling plate.

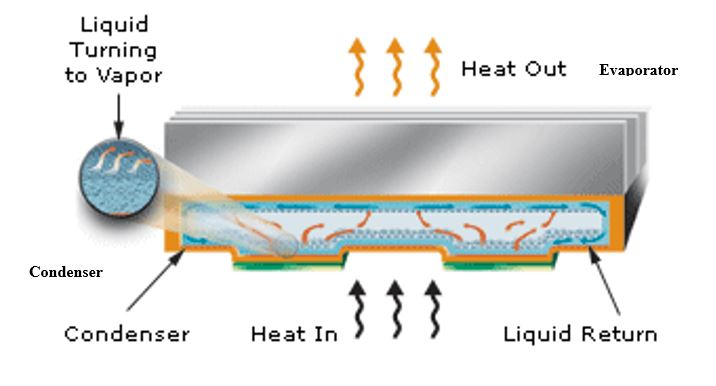

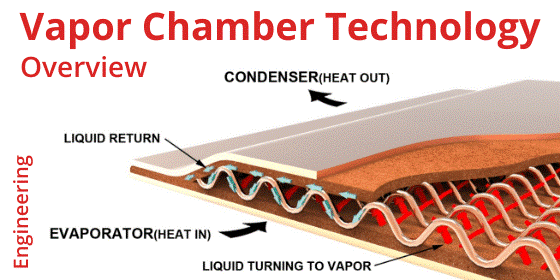

Basically, the vapor chamber helps to direct the heat in two dimensions. You can say that it is a planar heat pipe. When you apply heat fluxes and high powers to a very small evaporator area, you have to use vapor chambers. At the time when operation starts, the heat collected in the evaporator works by evaporation of liquid. The process takes place in an evaporator wick.

When the vapors start flowing through the chambers, an isothermal heat spreader is created. Then, condensation takes place and you get rid of heat through liquid cooling, natural convection, or forced convection.

On the other hand, a liquid cooling plate utilizes fluid for the transfer of heat. Another important point is that liquid cooling works in one direction while the vapor chamber transfers heat in two dimensions. The performance of a liquid cooling plate depends upon the fluid used in this system.

This is how both systems work effectively. For further details about selecting one among them, you need to read till the end!

What Is A Vapor Chamber?

A vapor chamber is also known as a vapor chamber heat spreader or a planar heat pipe. It works through a two-phase method in which it transfers heat from your heat source to the heat sink. This process is mostly utilized in electronic components where you need to get rid of collected heat.

Due to their high performance and effectiveness, vapor chambers are getting immense popularity across the globe. Vapor chambers work through different components that are listed below:

✓Vapor Chamber Enclosure

✓Vapor Chamber Wick Material

✓Vapor Chamber Working Fluid

✓Vapor Space Of Vapor chamber

Wick material and working fluid of the vapor chamber is housed in the vapor chamber enclosure. It is basically a sealed envelope. An important fact to note is that most vapor chambers are made of a copper enclosure, copper sintered wick, and water as a fluid.

How Do The Vapor Chambers Work?

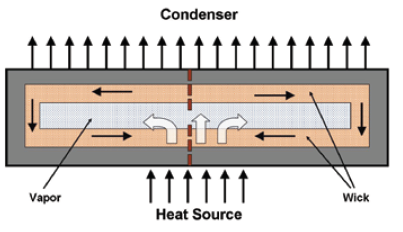

There exists a coolant in the Vapor chamber that changes its phase from liquid to gas when heated. Circulation of coolant occurs through convection. This coolant moves freely in the vapor chamber. After circulation, condensation of molecules occurs at the cold surface. The molecules dissipate their heat load and then get back to the coolant reservoir.

This way of working vapor chambers helps to get rid of a large amount of heat. Note that the rate of condensation keeps changing according to temperature change between the contact surface and the coolant. The vapor chamber is designed in such a way that there occurs automatic streaming of coolant toward the cold surface.

The self-organization of molecules is responsible for the thermal properties in the vapor chamber. This leads to evenly spread temperatures with stable nature on all surfaces of the vapor chamber. This process helps the vapor chamber to dissipate a large amount of heat.

Applications Of A Vapor Chamber

As a matter of fact, vapor chambers are being studied for the last seven years. Engineers discovered various issues in vapor chambers and incorporated them into various applications. Although there have come various challenges, vapor chambers are still getting better with time. Engineers are finding multiple ways to incorporate vapor chambers into different cooling systems.

The applications of vapor chambers have a wide range. This can be incorporated into the cooling system of PC, hard drive disk cooling, server cooling, and graphic card cooling. Moreover, these can also be used in high heat flux chips, tablets, phones, and LEDs.

Apart from all these applications, vapor chambers are also facing some limitations. For example, limitations come in applications where there comes a limitation in height. Moreover, you also need to use vapor chambers in hotspots applications but there is a challenge of weight, low airflow, and high ambient temperature.

Disadvantages Of A Vapor Chamber

Just like any other technology in this world, there are also limitations to vapor chambers. Some major benefits of a Vapor chamber are listed below:

✓Vapor chambers are expensive when compared to their alternatives.

✓You will see a higher minimum thickness in vapor chambers as compared to other options.

✓You cannot use vapor chambers as structural members without payment of the penalty for weight.

✓Standard vapor chambers possess a maximum temperature of 105⁰C. The temperature for enhanced vapor chambers is 150⁰C.

✓In vapor chambers, you have to keep the condenser and evaporator in parallel planes or the same plane.

What Is A Liquid Cooling Plate?

Today’s highly efficient technologies were made possible only due to effective thermal management methods. In devices where space is limited and power output requirement is higher, liquid cooling plates become essential. These plates help to attain a compact design and high thermal conductivity.

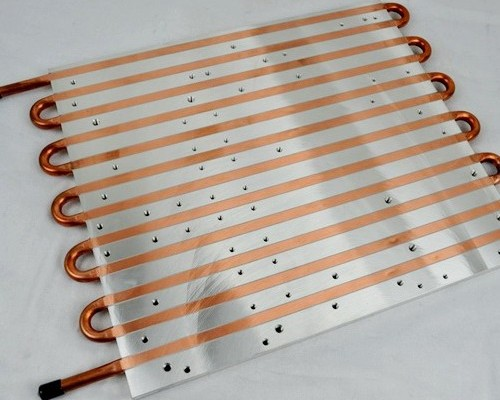

There are flow paths machined into the liquid cooling plates. The flow paths allow the heat-transfer fluid. When the heat is absorbed by the plates, the liquid cooling method is used to dissipate the heat.

The flow paths inside the liquid cooling plates can be of various sizes and shapes. Different shapes and sizes allow the dissipation of heat much more effectively. Basically, the effectiveness of heat transfer depends upon the surface area and size of flow paths.

It is important to note that there exist copper pipes or stainless steel pipes in liquid cold plates. It’s like they are embedded into the plate.

How To Choose Between A Vapor Chamber And A Liquid Cooling Plate?

It can be hard to decide whether you should use a vapor chamber or a liquid cooling plate. However, there are some factors explained below to help you figure out its solution.

When you need to achieve a genuine and two-dimensional heat spreading, then vapor chambers can be very helpful.

At the same time, vapor chambers are effective when you have to cool multiple or single microprocessors in case of a single plane. Vapor chambers are most effective when you require high heat flux applications.

On the other hand, there are circumstances when you need to choose liquid cooling plates. For example, when you need enhanced thermal conduction for cold rails, liquid cooling plates are effective.

Liquid cooling plates are most effective in cases where there is a requirement for smaller forced or natural convection heat sinks.

When you need to enhance the metal chassis assemblies and the card guides, you have to choose liquid cooling plates.

Conclusion

Apart from differentiating between vapor chambers and liquid cooling plates, there is another factor to consider. Even if you choose the right heat management system, you have to ensure that you get the right quality of the system. Not having a good quality thermal management system can only lead to damaging your device with excessive heat.

Choosing the right manufacturer is not a very tough task. You have to conduct research through the internet and your social circle. You will get to know about the low-quality and high-quality vapor chambers and liquid cooling plates.

If you are looking for a high-quality manufacturer for your thermal management system, you can Reach Us now.