A Skived Fin Heat Sink Supplier You Would Prefer

- 0.1mm fin thickness

- 0.1mm fin gap

- Thinner fin, larger heat dissipation area.

- No skive tooling required

- Cost-effective compare to heat pipe heat sink

We will assign a sales from China, USA or Singapore, wherever is near you, to get in touch with you.

Some Projects We Have Accomplished

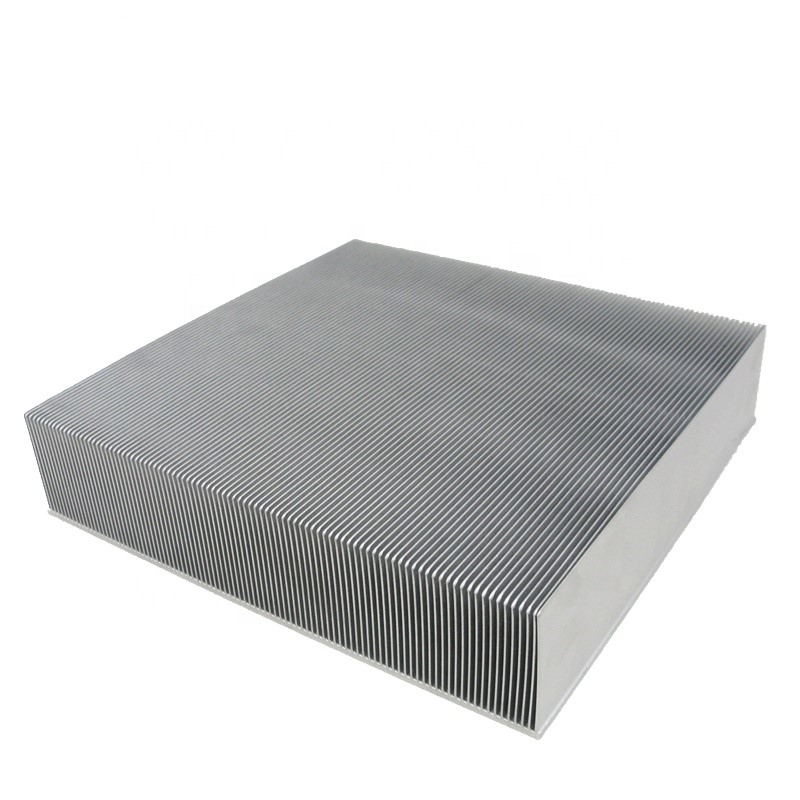

Aluminum skived heat sink

Material: AL1060

Process: Skiving + CNC machining

Finish: Degrease

Quality Control: Calliper, CMM

No tooling is required, no MOQ (minimum order quantity).

Material: CU1100

Process: Skiving + CNC machining + Screw assembly

Finish: Anti-oxidation

Quality Control: Calliper, CMM

No tooling is required, no MOQ (minimum order quantity).

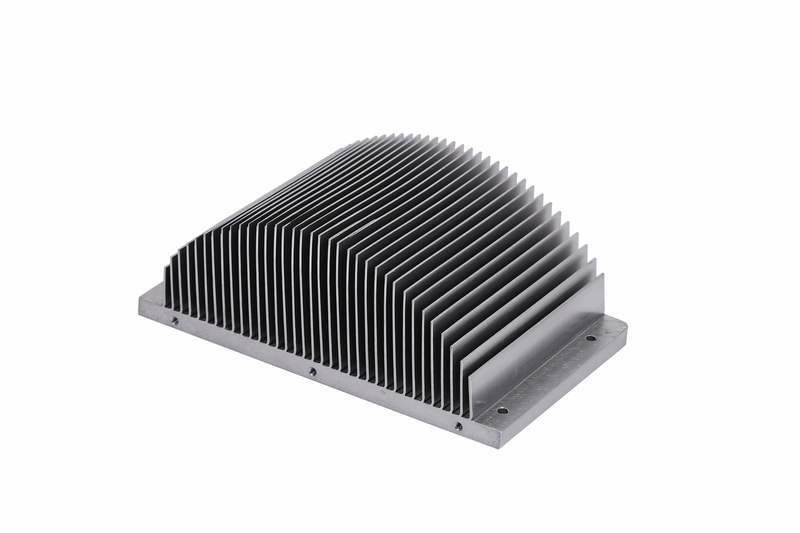

Skived Aluminum Heat Sink

Material: AL1060

Process: Skiving + CNC machining

Finish: Degrease

Quality Control: Calliper, CMM

No tooling is required, no MOQ (minimum order quantity).

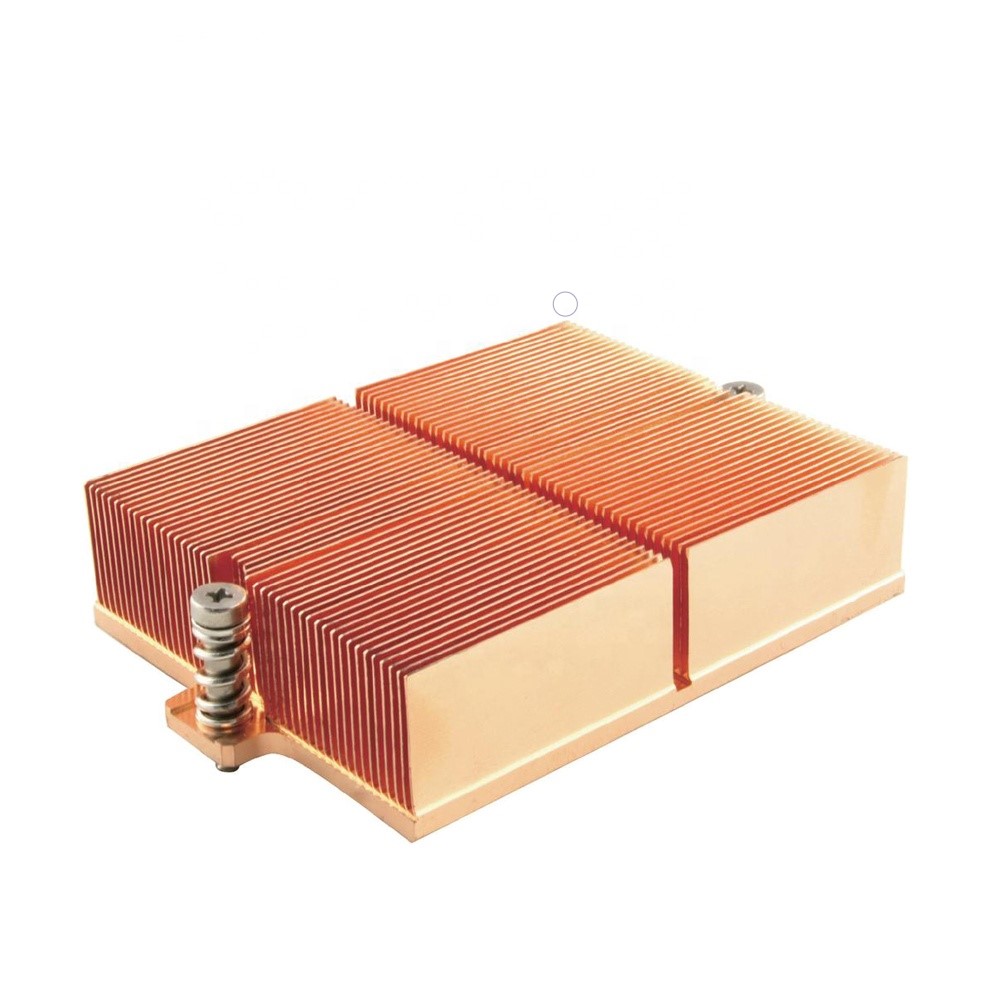

Skived Copper Heat Sink

Material: CU1100

Process: Skiving + CNC machining + Screw assembly

Finish: Anti-oxidation

Quality Control: Calliper, CMM

No tooling is required, no MOQ (minimum order quantity).

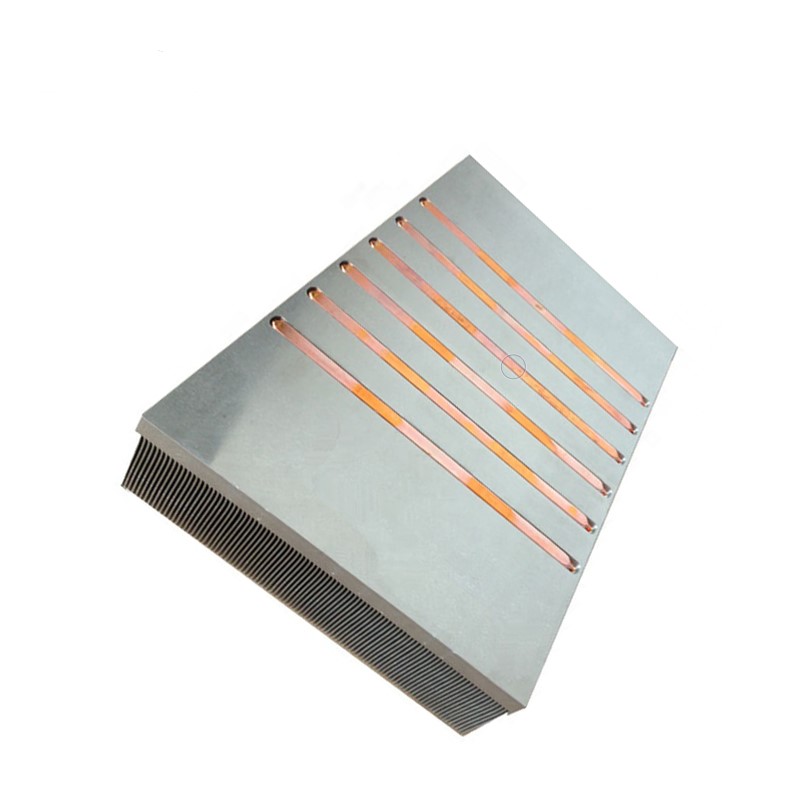

Skived Heat Sink With Heat Pipe

Material: AL6063+ Heat Pipe

Process: Skiving + Soldering + CNC machining

Finish: Nickel plated + Anti-oxidation

Quality Control: 100% on line thermal test, CMM

No tooling is required, no MOQ (minimum order quantity).

Skived Heat Sink For CPU

Material: CU1020 + AL1100 + Fan

Process: Skiving + Stamping

Finish: Anti-oxidation + degrease

Quality Control: 100% on line fan test, CMM

No tooling is required, no MOQ (minimum order quantity).

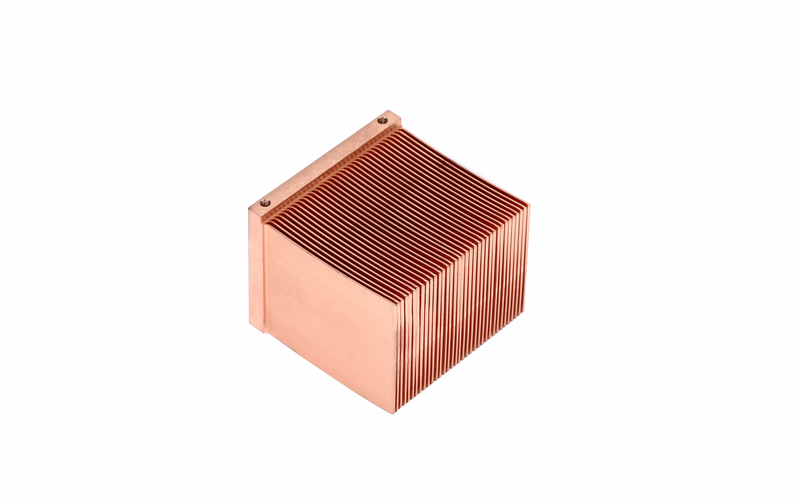

High Fin Aspect Ratio Skived Heat Sink

Material: CU1100

Process: Skiving + CNC machining

Finish: Anti-oxidation

Quality Control: Calliper, CMM

No tooling is required, no MOQ (minimum order quantity)

Aluminum Skiveing Heat Sink

Material: AL6063

Process: Skiving + CNC machining

Finish: Degrease

Quality Control: Calliper, CMM

No tooling is required, no MOQ (minimum order quantity).

Custom Skived Fin Heat Sink

Material: AL1060

Process: Skiving + CNC machining

Finish: Degrease

Quality Control: Calliper, CMM

No tooling is required, no MOQ (minimum order quantity).

Capabilities

Design Service

- Icepak, ansys, EFD, Flotherm for thermal design

- Computer Aided Design (CAD) and PROE for structure design

- Weight reduction

- Eliminate fans for a passive solution

- Projected cost of the final product

Prototype And Testing

- Rapid prototype build

- CMM and precision measuring tools

- Thermal measurement devices

- Thermal chambers

- Shock testing and cycling

- Salt spray testing for corrosion analysis

Serial Order Production

- State of the art machinery

- Strict quality control

- Latest production techniques

- Focus on continuous improvement

- Robust packaging design

Custom Heat Sink Manufacturer

If you are looking a custom heat sink manufacturer, then Pioneer Thermal is your right choice. We cover all the heat sink manufacturing process, with the industry-leading equipment and mature production line in house, we are able to provide top quality custom heat sink and meantime save your cost.

In addition, our experts always give manufacture suggestions when checking your drawing, or help to create a new design to suit your application.

Main Processes

- Extrusion

- Bonded Fins

- Skived Fins

- Snapped Fins

- Folded Fins

- Heat Pipes

- Cold Forge

- Die Cast

- Friction Stir Welding Cold Plate

- Gun Drill Cold Plate

- Vacuum Brazing Cold Plate

- Vapor Chamber

Finishing Processes

- CNC machining

- Stamping

- Drilling

- Tapping

- Screen Printing

- Anodizing

- Powder Coating

- Electrophoresis

- E-coating

- Chromate

- Passivation

- Laser Etching

- Polishing

Finishing Value Added

- Embedded fans

- Thermal Grease

- Phase Change Materials

- Gap Filler Pads

- Screws

- Springs

- Clips

- Embedded Heat Pipes

- Back Plates

- PEMs

- Standoffs

- Dielectric pads

- Compounds

Skived Fin Heatsink

A skived heat sink is a type of passive heat sink that uses precision machining to control its shape and surface roughness. Skiving is a process in which material is removed from a work piece using a cutting tool. The fins are produced by a tool that shaves fins up from an aluminum or copper base, then standing the fins up, the fin-to-gap aspect ratio is extremely high. This allows for the creation of very thin, flat surfaces with a high degree of accuracy.

Skiving can be used to create heat sinks with complex shapes and large surface areas, making them ideal for applications where space is limited. In addition, the use of skived heat sinks can improve the thermal performance of a system by reducing the thermal resistance between the heat sink and the surrounding air.

Skived Fin Heat Sink Manufacturing Process Video

The common material for skived fin heat sink is AL1060, AL6063, CU1100. You can choose either aluminum skived heat sink or copper skived heat sink for your application.

The high fin aspect ratio is what gives this heat sink its ability to maximize convection cooling. The shape of the heat sink fins play a major role in the overall cooling performance. Since it does not need soldering, the heat dissipation can reach the highest value.

Skived Fin Heat Sink Benefits:

- Skived heat sink has higher heat sink density to increase heat dissipation area and improve heat dissipation performance.

- The height of the fin of a skived heat sink can reach 120mm, which fully meets the production needs of most radiators.

- The fin of a skived heat sink can be made thinner, generally 1.5mm or even 1.0mm, which can make the heat sink lighter.

- The skived heat sink is shoveled up on the aluminum or copper base, so the heat dissipation efficiency of the aluminum and copper base is 100%

- High compatibility of skived heat sink, allow for second processing, and can also be used with the buried heat pipe process to improve the thermal performance.

On-demand Manufacturing

Skived fin heat sinks are made in a variety of shapes and sizes to suit a wide range of needs. Pioneer Thermal offers high quality but cost-effective skived fin heat sinks that come with a range of different features. Utilizing state-of-the-art equipment and techniques, our engineers design and manufacture custom heat sinks for a wide spectrum of applications.

With Pioneer Thermal, you’ll get the best in thermal management at a price you can afford without sacrifice the quality.

Contact us today to find out how we can help you.

We'd Love To Hear From You

-Find out how we can benefit your project

Hi partner, no matter you need new design & simulation for your new project, or you need heat sink manufacturing service for current on-going project, we are at your service.

What You Get When You Send Inquiry

- Less than 12 hours response to your message

- Professional advice on manufacturing process

- Seasoned design engineer help you to design a heat sink tailored to your needs

- Mature production line to save your cost

- Seamless communication to save your time

- A one-stop partner to make your work easier

You can always send inquiry with drawing to mia@ptheatsink.com