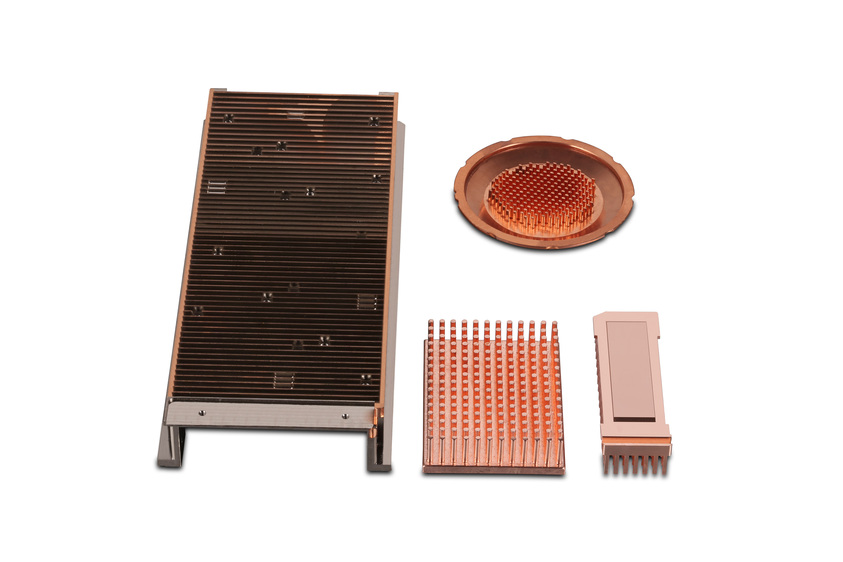

Pin Fin Heat Sink With High Quality and Timely Delivery

- Better heat dissipation

- Excellent surface finish

- Better thermal conductivity

- Cold forging machines up to 2000 tons can accommodate larger sizes

- Professional mold design, structural design and thermal design greatly shorten the product development cycle time

- Manufacture suggestions is always provided on quote stage

- One-stop service from raw materials to finished products to shipment

- Branch office in USA & Singapore to offer timely response

We will assign a sales from China, USA or Singapore, wherever is near you, to get in touch with you.

What Is Pin Fin Heat Sink?

A pin fin heat sink is a type of heat sink that consists of a metal base with a series of small pins that protrude from the surface. The component to be cooled is attached to the base of the heat sink, and the pins help to increase the surface area for better heat transfer. In addition, the pin fin heat sink can be used in conjunction with a fan to provide active cooling. This type of heat sink is often used in high-powered electronics such as CPUs and GPUs.

They are also used in applications where space is limited, such as in handheld devices. Pin fin heat sinks typically have a high thermal conductivity and a low density, which makes them ideal for use in applications where weight is a concern.

Pin Fin Heat Sink Process

Pin fin heat sink is use of a forging machine to apply pressure to the metal billet through the tooling, so that the material produces plastic deformation, changing its original size, shape and performance, so as to obtain the desired shape and size of the forming processing method.

The common material used for cold forge heat sink is:

- AL6063

- AL1070

- CU1100

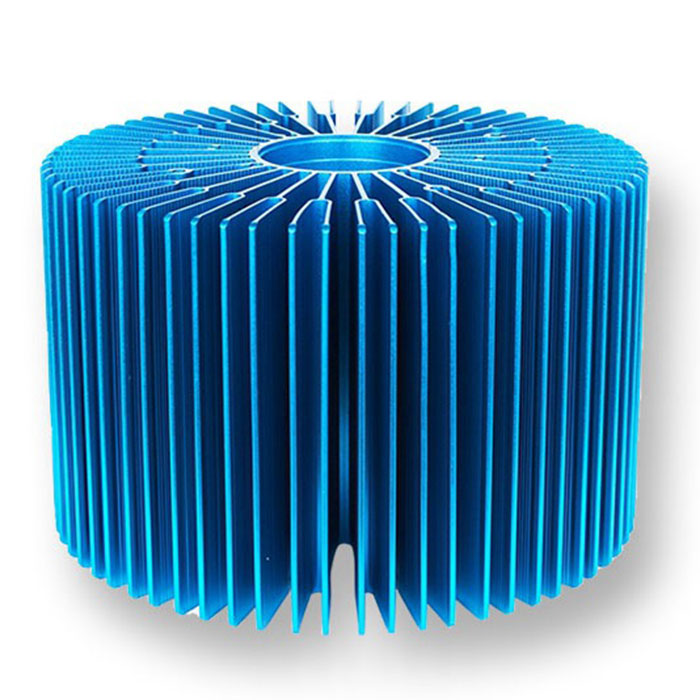

Available surface treatment:

- Anodizing

- Nickel plated

- Chromate

- Painting/E-coating

- Powder coating

Cold Forge Heat Sink Manufacturing Process Video

Advantages of Cold Forged Heat Sink

- Achieve less cutting or cutting-free processing

- save the cost of raw materials.

- High production efficiency, high strength, high precision, high surface finish.

- Not only can replace the traditional die cast heat sink and extrusion heat sink, but cost performance is also better.

- With its unique characteristics, forging can also make complex shapes that other processes can not make, to meet the special performance requirements of some products. Product applicability is stronger.

High Quality, High Precision Forged Heat Sink at Pioneer Thermal

When it comes to thermal management, there is no one-size-fits-all solution. Rather, the most effective approach is often to customize the heat sink to meet the specific needs of the application. Pioneer Thermal understands this, which is why we offer custom cold forge heat sinks.

We can tailor the size, shape, and fins of the heat sink to meet the precise requirements of your project. Our team of engineers will work with you to design a heat sink that meets the specific needs of your project. In addition, we offer a variety of finishes and coating options to help protect your heat sink from the environment. We use the latest cold forging technology to produce our heat sinks, which results in a high-quality product that is both durable and cost-effective.

If you need a custom cold forge heat sink, be sure to contact Pioneer Thermal. Our team in China, USA & Singapore will be happy to discuss your needs and formulate a solution that meets your unique requirements.

Our Capabilities

Design Service

- Icepak, ansys, EFD, Flotherm for thermal design

- Computer Aided Design (CAD) and PROE for structure design

- Weight reduction

- Eliminate fans for a passive solution

- Projected cost of the final product

Prototype And Testing

- Rapid prototype build

- CMM and precision measuring tools

- Thermal measurement devices

- Thermal chambers

- Shock testing and cycling

- Salt spray testing for corrosion analysis

Serial Order Production

- State of the art machinery

- Strict quality control

- Latest production techniques

- Focus on continuous improvement

- Robust packaging design

Successful Projects We Have Accomplished

We'd Love To Hear From You

Hi partner, no matter you need new design & simulation for your new project, or you need heat sink manufacturing service for current on-going project, we are at your service.

What You Get When You Send Inquiry

- Less than 12 hours response to your message

- Professional advice on manufacturing process

- Seasoned design engineer help you to design a heat sink tailored to your needs

- Mature production line to save your cost

- Seamless communication to save your time

- A one-stop partner to make your work easier

You can always send inquiry with drawing to mia@ptheatsink.com