Introduction

In a world of the latest technologies, heat sinks are becoming an important part to improve the efficiency of devices. Heat sinks are used to keep your devices within the allowable temperature limits. This ability of heat sinks makes them perfect to be used in devices ranging from motor drivers to CPUs.

There are multiple options available for heat sink designs in the market. But selecting the most efficient heat sink design can be a little confusing. If you are also going through the same confusing situation, Don’t worry. This article has listed and explained all the important factors that help to make an efficient heat sink design for your device.

Heat Sinks – Thermal Management Systems

Heat sinks are known to be mechanical devices that are mounted to electrical devices to help them function effectively.

The heat is dissipated into the environment through a heat sink. This environment can be either an air Environment or fluid. The fluid can be water or any other coolant.

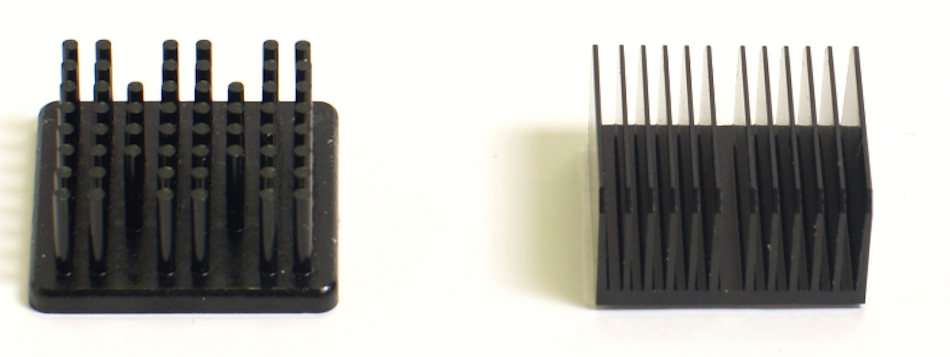

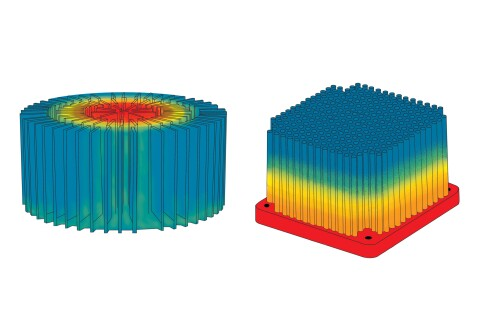

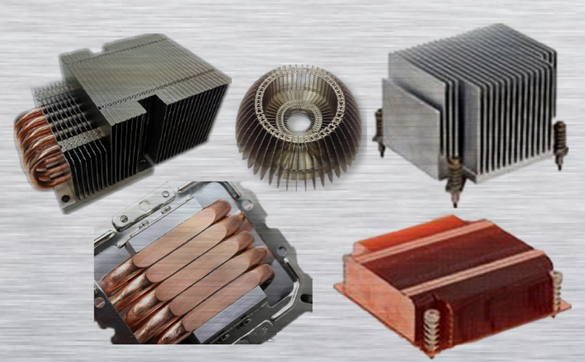

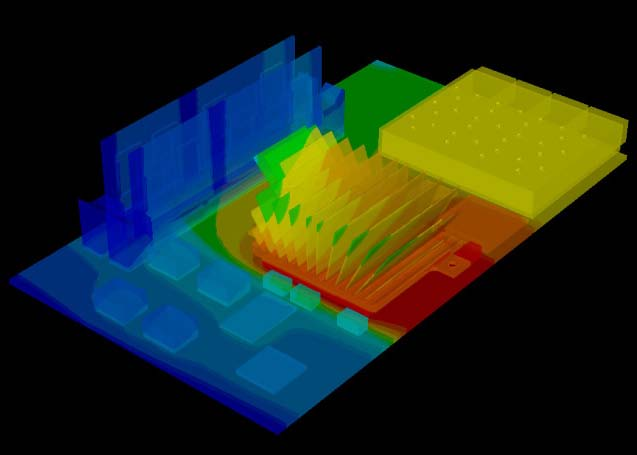

Heat sink designs are usually composed of copper or aluminum material with pins or fins to facilitate heat transfer.

When deciding about the most efficient heat sink design, you will see two common designs on the market.

- Aluminum Heat Sinks – Cheaper and Good Thermal Conductivity.

- Copper Heat Sinks – Costly And Higher Thermal Conductivity.

This is to say that when you need a device that has to operate at higher temperatures. You need to prefer copper heat sinks. When there is no high-temperature environment then you can choose the aluminum design as it is cheaper.

Electronics can produce a lot of heat due to the low efficiency of electrical components within them. This leads to the fact that the generated heat should be dissipated. As your electrical devices may not withstand the high amount of heat generated.

For example, there is a maximum junction operating temperature for circuits. It is specified as 130⁰ by L298 in the datasheet. Now if the temperature generated in the circuit exceeds the maximum junction operating temperature, there can occur some damage.

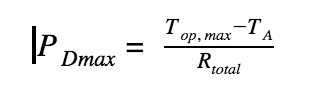

To deal with the above situation, you should have an idea about the amount of heat that a device can generate. Based on this measurement, you can design an efficient heat sink. The formula listed below can help to find out the maximum power dissipation:

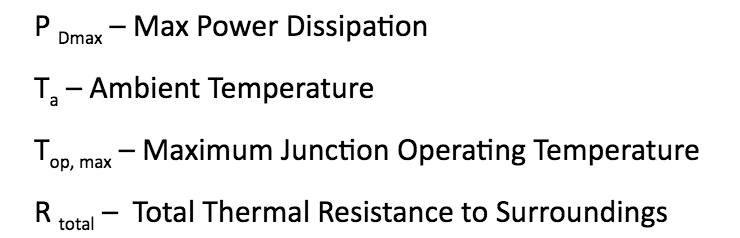

Where :

The ambient temperature refers to room temperature for many open electrical devices. However, this temperature can rise if the electrical devices are kept with other heat-generating devices. An interesting point to note is that the ambient temperature can be higher if your device is kept outside in the hot summers.

On the other hand, thermal resistance refers to the rise in temperature per watt of power dissipation. According to the datasheet for L298, the thermal resistance is 35⁰ C/W.

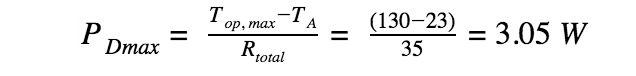

Putting all these values in the formula given above, you will get the following value:

Some Other Important Calculations To Design Heat Sinks

- Dissipation Of Power In IC

- Thermal Resistance

- Selection Of Heat Sink Compound

- Heat Source Quantity (how many contact points)

- Heat Source Position

- Fan specifications

Additional Factors That Affect Efficiency Of Heat Sinks Design

For all the factors listed above, you have to make sure that you perform accurate calculations. However, you will be amazed to know that having accurate calculations for heat sink design is not enough for high efficiency. There exists some other ways to design a most efficient heat sink system.

When you are designing your heat sinks, you have to remember a few main definitions listed below:

- Conditions Of Thermal Heat Sink Compound

It is not enough to have only a well-rated compound for your thermal heat sink. But you have to ensure that there exists enough thickness to fill the gap between the heat sink and the component. Note that if the thickness of the gap is too high, it will cause slow heat transfer through your heat sink design.

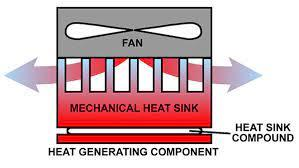

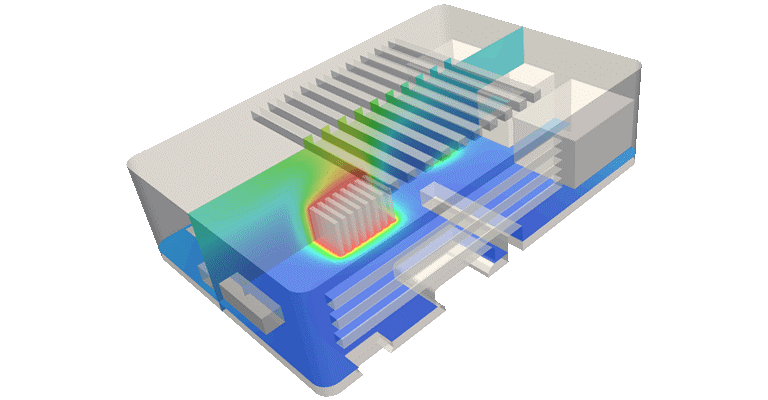

- Natural And Forced Convection

Basically, there are two ways to get rid of heat out of your device. It can be either an active heat sink design or a passive heat sink design. The passive ones carry natural convection while the active ones carry forced convection to dissipate the heat.

If you want the most efficient heat sink design, then forced convection can be a better option. It is due to the use of heatsink fans that push the air more effectively. Using this method will also increase the rate at which heat will be transferred. It will ensure that the ambient air is at a low temperature while lowering the effective thermal resistance.

On the other hand, if your heat sink is closed in a very congested package, it will cause restrictions in airflow. It will result in the hampering of natural convection. Hence, reducing the heat sink’s effectiveness and efficiency.

Important Points

Ensuring the reliability and efficient design of your heat sinks is very important for the proper functioning of your device. Heat Sink material and heat sink designs are the most important things to consider when designing heat sinks.

- The thermal management of your designed device can be improved by using the formulae given above. It can also be improved by considering all the factors explained earlier.

- An important point for you to note is that you can also make these calculations with the help of a heat sink calculator. You can easily find it online.

- According to experts, the most efficient heat sink design is the one that contains pins or fins. This is because the surface area is increased for the transfer of heat.

- If you have to design an efficient heat sink, you should consider using copper material. Although it has higher costs it possesses amazingly high thermal conductivity. However, most people still prefer aluminum since it gives relatively high thermal conductivity at low costs.

- In other words, Copper heat sinks designs are more efficient than aluminum heat sink designs.

- Having pins or fins in your heat sink design ensures forced convection and hence more efficient design.

- A heat sink absorbs thermal energy from the electrical device and dissipates it through heat transfer’s conduct method.

- For an efficient heat sink design, a powerful fan can be a game changer. Since a powerful fan will provide a higher air flow rate over a surface, it will also increase the rate at which heat is transferred. Hence, drawing a higher amount of heat energy away from the device.

Implementation of all these factors will help you get the most efficient heat sink design.

The Bottom Line

Efficiency is considered important for whatever device you buy. Without efficiency, the devices cannot work with perfection. It is especially true for those devices that generate a high amount of heat and need it to get dissipated. At the same time, the proper dissipation of electrical devices depends on heat sinks.

This is why you need to have an efficient heat sink design. Before designing a heat sink, you need to perform certain calculations for your device. With the help of those measurements, it is easy to design the most efficient heat sinks.

If you are looking for a manufacturer to help you in all this process, look no longer. We are here to help you out. Contact Us now.