Introduction

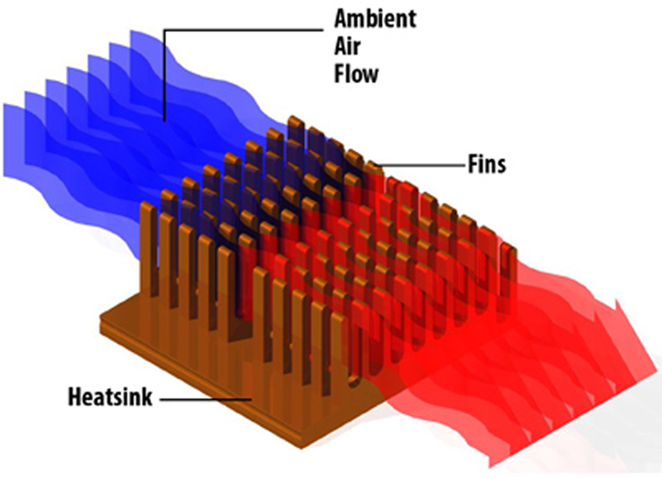

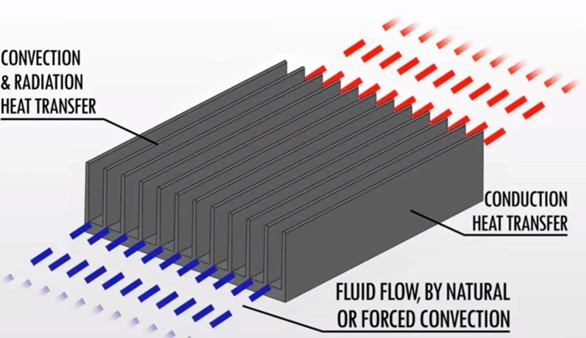

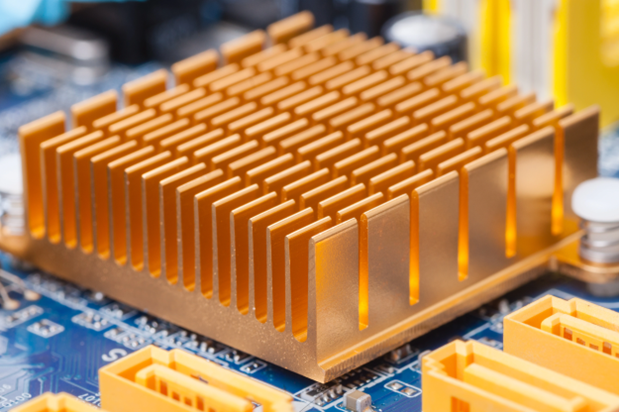

Heat sinks are devices used for cooling objects that get hot while being used. Nowadays, a large number of electrical and mechanical objects use heat sinks to effectively dissipate their heat. So what does a heat sink do? It simply dissipates the energy generated by the object attached to it.

If you want to know why it is necessary to use a heat sink. Then the answer is simple. It improves the performance as well as extends the life of objects attached to it. As a result, the object runs more efficiently with higher productivity.

If you want in-depth knowledge about heat sinks then this is the right place to learn. Continue reading!

Heat Sink & Its Functions

The basic function of the heat sink has become very clear from the introduction part. It is generally a device to dissipate heat generated by the object that contains it.

Moreover, it is necessary to have a heat sink if you want to increase the life, efficiency, and productivity of your object.

Without a heat sink, your electrical or mechanical products will build up a large amount of heat. This situation will result in injury, explosion, failure, fire, or other such situations. In this situation, heat sinks absorb and then dissipate the heat generated by your mechanical and electrical devices.

Different Types Of Heat Sinks Available In Market.

Generally, heat sinks are broken down into different categories. However, the two main categories are:

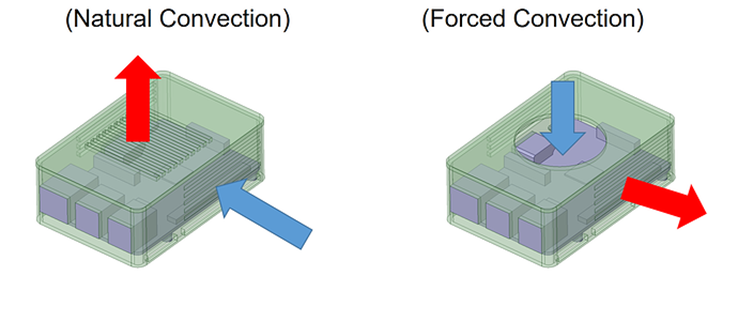

Active Heat Sink

These heat sinks consist of a blower or fan. The most common type of active heat sink is a ball-bearing motor fan.

Passive Heat Sink

This type of heat sink uses a convection process for the removal of heat energy. It is due to the absence of mechanical components.

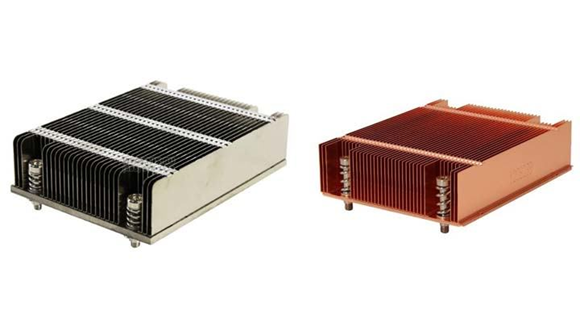

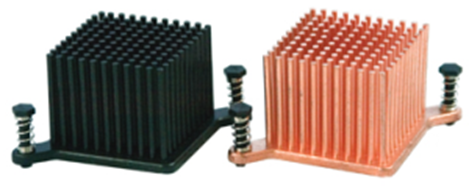

On the basis of material composition, heat sinks are divided into two types:

Aluminium Heat Sinks

This type of heat sink is most commonly used for different devices. It has the ability to fit the needs of most projects. It possesses excellent thermal conductivity with a lightweight metal.

Copper Heat Sinks

It possesses thermal conductivity better than that of aluminum heat sinks. However, it has more weight and high costs.

Heat sinks are manufactured based on different procedures. The different manufacturing procedures have divided the heat sinks into six further types. All those six types are listed below:

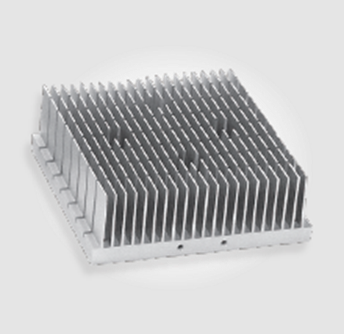

Extrusion Heat Sinks

In this type of heat sink, the manufacturing material is extruded aluminum. This type of process is most effective for many applications. The performance of extrusion heat sinks lies in a range of low to high.

Advantages:

Low Cost

Highly Customization

Disadvantages:

Limited dimensions due to maximum extrusion width.

Bonding Heat Sinks

Bonding heat sinks are manufactured for large-sized applications.

Advantages

Different fin material and base material

Aluminum and copper combination of fin material

Improved thermal performance

Lightweight

Disadvantages

Moderate overall performance

High costs

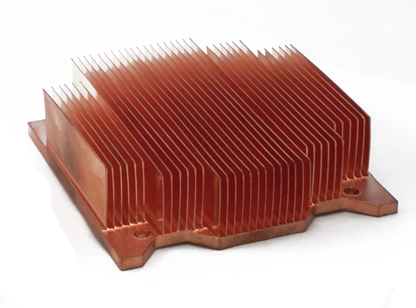

Skived Heat Sinks

This type of heat sink is manufactured from a solid block of metal. The most commonly used material in this type is aluminum and copper.

Advantages

High design flexibility

High fin density

More heat dissipation

Offers medium to high performance

No tooling required

Disadvantages

Expensive compare to extrusion heat sink

Thermal conductivity is entirely determined by the material of the heat sink

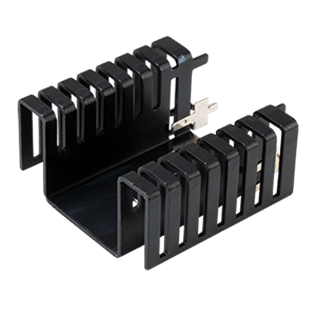

Stamped Heat Sinks

This type of heat sink contains a process in which stamping of metal fins is performed. After the stamping process, the fins are soldered onto the base if applicable. Low power applications require pure stamped heat sinks.

Advantages

Low cost

Ease of production automation

Disadvantages

Low performance compare to other type of heat sink

Heat Pipe Heat Sinks

Heat pipe heat sink is usually consists of stamped fins, heat pipe and aluminum or copper base, fins and heat pipe are soldered to base by reflow oven.

Advantages:

High thermal conductivity

Small size and light weight

High heat dissipation efficiency

No external power supply is required

Has very good isothermal

Disadvantages

Cost is higher compare to extruded heat sink and skived heat sink

Forged Heat Sinks

This type of heat sink is manufactured using compressed copper and aluminum. The best part about them is their multiple applications. These types of heat sinks can be hot forged or cold forged.

Advantages

Low cost for high volumes

Low material consumption

Good strength properties

Disadvantages

Medium cooling performance

Limited design capabilities.

Die Cast Heat Sink

Die casting is a precision casting method that uses high pressure to force molten metal into a complex shaped metal mold.

Advantages

Complex shape

Well-defined contours

Thin-walled deep cavities

Cheap cost for high volume

High capacity

Disadvantages

High tooling cost

Not suitable for small batch production

CNC Machined Heat Sinks

Advantages

Higher thermal conductivity

Most complex geometries can be achieved

Plenty of flexibility

Disadvantages

Higher costs compare to other heat sink

Less ideal for high volumes.

How To Choose The Right Heat Sink?

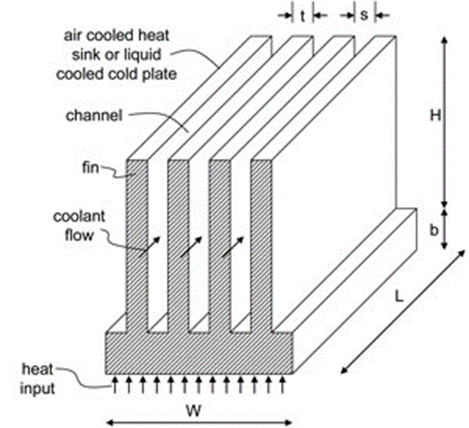

Heat sinks are considered very helpful for heat transfer. However, choosing the right heat sink can also be a very tough task. Here are some points you need to consider:

You have to make sure that you have chosen the right heat sink type according to your thermal resistance needs.

You need to consider your heat sink design needs.

You also need to make sure that you choose the right material composition. For example, if you want higher thermal conductivity then you should choose copper Heat Sinks. On the other hand, if you want to save your costs then you should go for aluminum heat sinks.

You have to consider whether you are looking for an active heat sink or a passive heat sink. For example, if you are looking for enhanced heat dissipation then active heat sinks are ideal. However, if you want something cheaper then passive heat sinks are best. You will be amazed to figure out that some heat sinks also possess liquid coolers.

Based on different manufacturing procedures, each heat sink possesses pros and cons. You can make an effective decision based on the pros and cons of your heat sinks.

Apart from all these factors, it is also important to consult an expert while buying the right heat sink. The right manufacturer can turn out to be your true advisor. To choose the right manufacturer is another big topic, bottom line is: not only they should have rich experience in producing heat sink, they also should know how to make heat sink design. If they have wealthy heat sink experience, then they should faced a lot of production problem and have the problem-solving capability. If they know heat sink design, they can give you very valuable suggestions to improve the thermal management. The right manufacturer will guide you and customize the heat sink according to your requirements.

Conclusion

Knowing the basic function of heat sink makes you realize their Importance for your devices. If you want to make your devices last longer then using a heat sink as a cooler is considered important. Moreover, you also need to choose the right heat sink for your device. And for the right heat sink selection, it is important to choose the right manufacturer. If you want to know about a manufacturer who can customize your heat sink, then Contact Us now.