Build prototype in

7 days

Your own heat pipe heat sink factory in China

In the past 21 years, we have designed 3000+ projects, 95% build prototype, 85% are in mass production. 100% on-line thermal test is performed to ensure only high quality heat pipe heat sink is delivered to you.

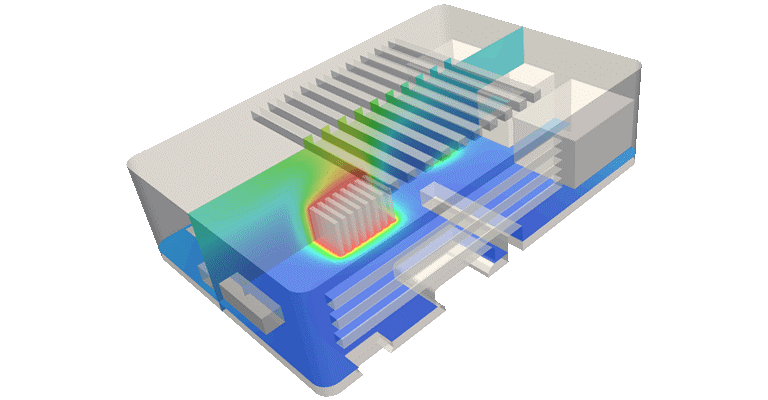

From manufacturing point of view, there are five main types of heatsink with heatpipe:

- Extruded heat sink with heat pipe

- Die cast heat sink with heat pipe

- Pin fin heat sink with heat pipe

- Stamping fin heat sink with heat pipe

- CNC machining heat sink with heat pipe

Check this link for more details. Pioneer Thermal is the leading heat pipe heat sink manufacturer in China, and has rich experience in producing heat pipe heat sink, below are some of our mass production projects:

Own heat sink factory

75000 foot square facility with mature production line covering CNC machining, extrusion, stamping, cold forging, die casting, skiving fin, heat pipe heat sink, water cooling plate, friction stir welding, vapor chamber and heat sink assembly.

Own heat pipe factory

5 sintering furnace, copper heat pipe monthly capacity 800k. Ultra thin heat pipe height 0.4mm.

No MOQ

No MOQ required for customized heat pipe heat sink.

Customizable processes

Press fit, epoxy, bonding, soldering, heat pipe insert fin, whatever process suits your project, we can make it.

Customizable thermal resistance

When designing the heat pipe heat sink, we can reduce the thermal resistance by optimizing the heat pipe connection between the heat generating and cooling areas

Quick Turnaround

Prototype can be finished in 7 days, production can be finished in 21 days. From heat pipe to finished heat sink, all processes are done in our own factory, so we can well control the quality and have flexible L/T based on your urgency.

Our R & D team has 10 design engineers with bachelor degree and 12+ years’ design experience.

12+ years design experience

each R & D engineer has been working in heat sink factory over 12 years.

More than 3000+ design

with the rich experience, our skilled R & D engineer can design a heat sink tailored to your needs within 3 working days.

95% of the cases prototyped

after design finished and approved, we build prototype to verify the thermal performance within 7 days.

" We Have Commited To Perfect Work For Get Perfect Heat Sink Services "

Our heat pipe heat sink contains below main processes:

- Extruded baseplate

- Stamping fin

- CNC machining baseplate

- Cold forge baseplate

- Die cast baseplate

- Heat pipe soldering

- Heat pipe press fit

- Heat pipe bonding

- Heat pipe epoxy

- 100% on-line thermal test

Incoming Inspection

- Fin/Base raw material: check material grade is correct

- Heat pipe: check dimension, cosmetic and Qmax meets drawing

- Screw: check material, surface finish and thread meets the requirement

Spring: check material, surface finish, elasticity parameters meets the specification

- Pad: check brand, material, cosmetic meets drawing

In-Process Inspection

- Check fin & base material, dimension, surface finish (film thickness) and cosmetic meets the requirement

- Check reflow oven temperature curve

- Check soldering paste meets specification

- Perform pull force test to make sure soldered well

- Perform first article inspection and AQL to ensure all dimensions are within specification

Finished Product Inspection

- Check dimension by calipers, height gauge & CMM

- 100% thermal test by automatic thermal test line to ensure performance

- Visual inspection is performed to verify that there are no cosmetic defects

- FAI, RoHS & SGS is always provided to customer

Out-Going Inspection

- Cosmetic Inspection

- Drop Test

- Vibration Test

- Label information

What is our client saying

Let's Boost Your Business