A Guide to Choosing the Right Cold-Forged Heat Sink for Your Application

At Pioneer Thermal, we understand that selecting the right heat sink for your application can feel overwhelming. With over 21 years of experience as a

At Pioneer Thermal, we understand that selecting the right heat sink for your application can feel overwhelming. With over 21 years of experience as a

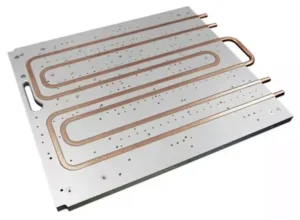

Compared to the GB200, the GB300 takes a bold step forward in liquid cooling design. The most significant change is the innovation of the cold plate structure: GB300 abandons the model of covering multiple chips with a large cold plate, and instead equips each chip with an independent “one-in-one-out” liquid cooling plate

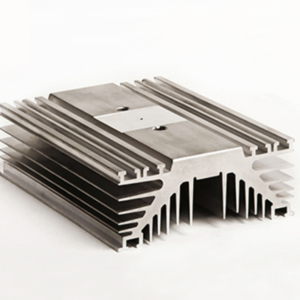

When it comes to keeping electronic components cool and running efficiently, choosing the right heat sink is crucial. At Pioneer Thermal, we specialize in providing

When it comes to modern electronics, managing heat is one of the most critical aspects of ensuring performance, longevity, and reliability. At Pioneer Thermal, we

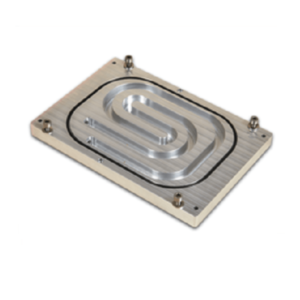

At Pioneer Thermal, we specialize in designing and manufacturing cutting-edge cooling solutions tailored to your needs. Among our most advanced offerings is the custom liquid

In the ever-evolving world of electronics, effective thermal management is no longer a luxury—it’s a necessity. As electronic devices become faster, smaller, and more powerful,

In the world of advanced technology and electronics, keeping devices cool is essential. Without proper cooling, high-powered components can overheat, leading to reduced efficiency or

Artificial Intelligence (AI) technologies are advancing at an unprecedented pace, with applications ranging from autonomous vehicles to complex data analysis. This rapid evolution demands high-performance

In the dynamic world of artificial intelligence, innovation and efficiency go hand in hand. AI systems, from machine learning applications to advanced robotics, rely on

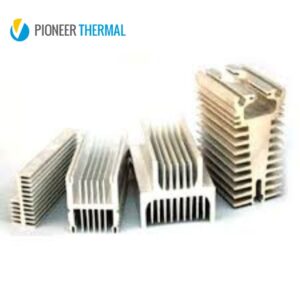

In high-performance electronics, efficient cooling solutions are essential to keep systems running smoothly and extend their lifespan. For many industries, from telecommunications and data centers

Pioneer Thermal is your one-stop heat sink supplier, we support design, simulation, prototype build, low volume run and serial order production.

Your drawing and projects are safe with us, we will not disclose any information without your approval.

Or send email to mia@ptheaksink.com directly