Vapor Chamber Heat Sink Design And Production

- VC heat transfer efficiency is faster than heat pipe

- Suitable for high heat flow density electronic components

- Variable thickness options, up to 2.0mm thin

- Direct contact with heat source seamlessly

- Unlimited structure, suitable for high and low multi-heat source

We will assign a sales from China, USA or Singapore, wherever is near you, to get in touch with you.

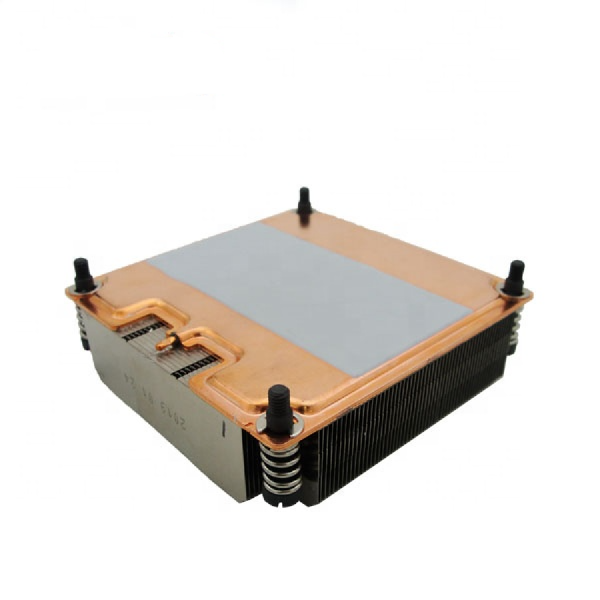

Vapor Chamber Heat Sink

Vapor Chamber Heatsink is constructed from sealed copper plates and filled with a small amount of fluid such as deionized water that allows heat to be rapidly dispersed away from the source. Inside the chamber resides an internal support structure to prevent the buckling of chamber walls. Classified formally as a heatpipe, a vapor chamber is one of the best heat spreading options at the base of a heatsink; and typically used for high power devices. When combined with stamped fins, it creates a high-end thermal management device that can rapidly spread heat from a small source to a large surface area.

A Vapor Chamber Heatsink can be integrated with either aluminum or copper heatsinks. The simplest method is to solder a vapor chamber to the base of an extruded heatsink. A more thermally efficient method is to solder a stack of stamped fins directly to the surface of a vapor chamber. To improve the dimensional integrity, these fins are often interconnected by locking tabs called zipper fins.

Custom Heat Sink Manufacturer

If you are looking a custom heat sink manufacturer, then Pioneer Thermal is your right choice. We cover all the heat sink manufacturing process, with the industry-leading equipment and mature production line in house, we are able to provide top quality custom heat sink and meantime save your cost.

In addition, our experts always give manufacture suggestions when checking your drawing, or help to create a new design to suit your application.

Main Processes

- Extrusion

- Bonded Fins

- Skived Fins

- Snapped Fins

- Folded Fins

- Heat Pipes

- Cold Forge

- Die Cast

- Friction Stir Welding Cold Plate

- Gun Drill Cold Plate

- Vacuum Brazing Cold Plate

- Vapor Chamber

Finishing Processes

- CNC machining

- Stamping

- Drilling

- Tapping

- Screen Printing

- Anodizing

- Powder Coating

- Electrophoresis

- E-coating

- Chromate

- Passivation

- Laser Etching

- Polishing

Finishing Value Added

- Embedded fans

- Thermal Grease

- Phase Change Materials

- Gap Filler Pads

- Screws

- Springs

- Clips

- Embedded Heat Pipes

- Back Plates

- PEMs

- Standoffs

- Dielectric pads

- Compounds

Capabilities

Design Service

- Icepak, ansys, EFD, Flotherm for thermal design

- Computer Aided Design (CAD) and PROE for structure design

- Weight reduction

- Eliminate fans for a passive solution

- Projected cost of the final product

Prototype And Testing

- Rapid prototype build

- CMM and precision measuring tools

- Thermal measurement devices

- Thermal chambers

- Shock testing and cycling

- Salt spray testing for corrosion analysis

Serial Order Production

- State of the art machinery

- Strict quality control

- Latest production techniques

- Focus on continuous improvement

- Robust packaging design

Successful Projects We Made

We'd Love To Hear From You

Hi partner, no matter you need new design & simulation for your new project, or you need heat sink manufacturing service for current on-going project, we are at your service.

What You Get When You Send Inquiry

- Less than 12 hours response to your message

- Professional advice on manufacturing process

- Seasoned design engineer help you to design a heat sink tailored to your needs

- Mature production line to save your cost

- Seamless communication to save your time

- A one-stop partner to make your work easier

You can always send inquiry with drawing to mia@ptheatsink.com